Product Description

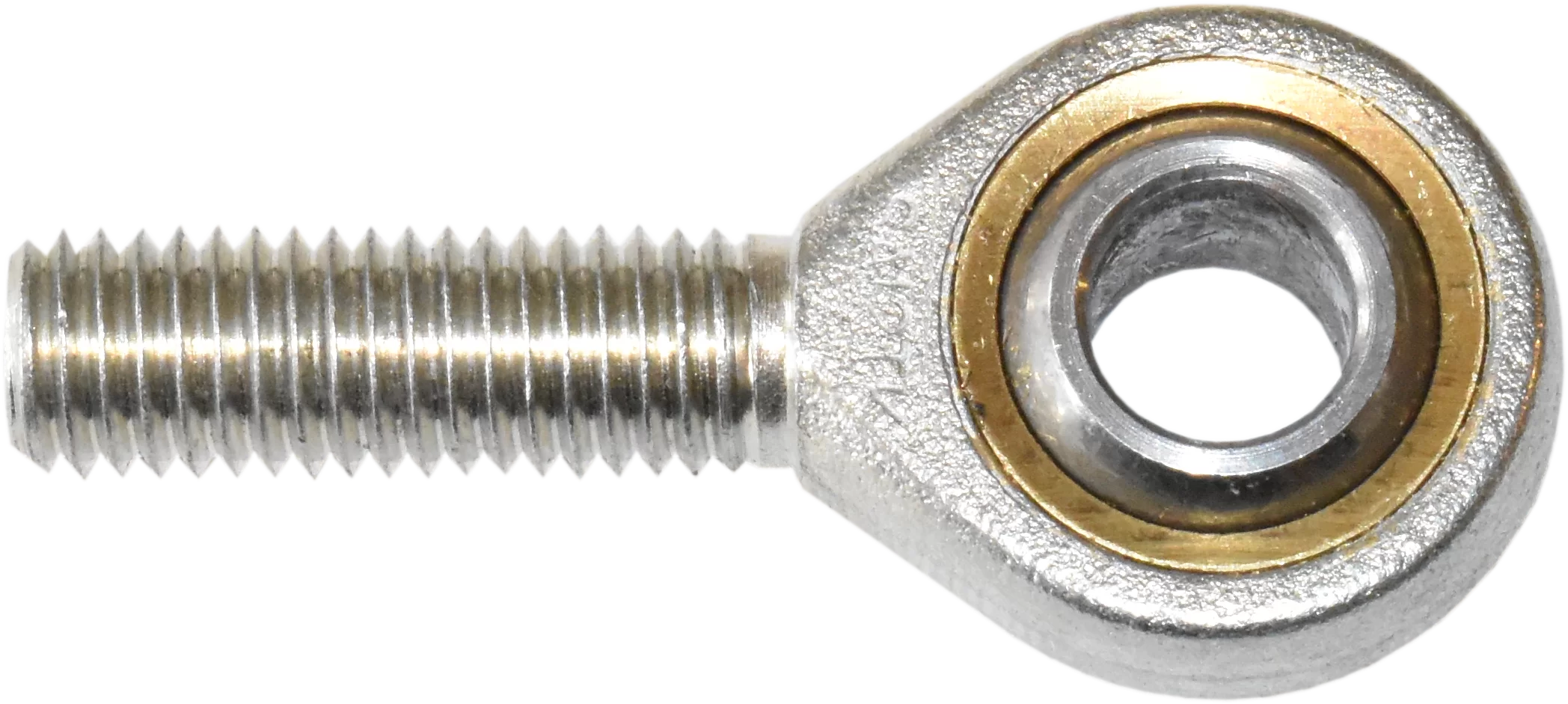

SA…TK Series Rod Ends is belong to maintenance-free Rod Ends bearing. The rod end body is equipped with a left-hand or right-hand external thread. The rod end body is formed by extrusion and the surface of the rod end body is galvanized. And The outer sphere is lined with PTFE synthetic material.

PRODUCTS CATALOGUE

| Part No: | Dimension | Load Rating(KN) | Weight | |||||||||||

| d | B | dk | C1 | d2 | G | h | L1 | L2 | R1S | a | Cr | Cor | g | |

| SA5T/K | 5 | 8 | 11.11 | 6 | 18 | M5X0.8 | 33 | 19 | 42 | 0.3 | 13 | 5.7 | 6 | 13 |

| SA6T/K | 6 | 9 | 12.7 | 6.75 | 20 | M6X1.0 | 36 | 21 | 46 | 0.3 | 13 | 7.2 | 7.65 | 20 |

| SA8T/K | 8 | 12 | 15.875 | 9 | 24 | M8X1.25 | 42 | 25 | 54 | 0.3 | 14 | 11.6 | 12.9 | 38 |

| SA10T/K | 10 | 14 | 19.05 | 10.5 | 28 | M10X1.5 | 48 | 28 | 62 | 0.3 | 13 | 14.5 | 18 | 55 |

| SA12T/K | 12 | 16 | 22.225 | 12 | 32 | M12X1.75 | 54 | 32 | 70 | 0.3 | 13 | 17 | 24 | 85 |

| SA14T/K | 14 | 19 | 25.4 | 13.5 | 38 | M14X2.0 | 60 | 36 | 78 | 0.3 | 16 | 24 | 31 | 140 |

| SA16T/K | 16 | 21 | 8.575 | 15 | 42 | M16X2.0 | 66 | 37 | 87 | 0.3 | 15 | 28.5 | 39 | 210 |

| SA18T/K | 18 | 23 | 31.75 | 16.5 | 46 | M18X1.5 | 72 | 41 | 94 | 0.3 | 15 | 42.5 | 47.5 | 290 |

| SA20T/K | 20 | 25 | 34.925 | 18 | 50 | M20X1.5 | 78 | 45 | 103 | 0.3 | 14 | 42.5 | 57 | 380 |

| SA22T/K | 22 | 28 | 38.1 | 20 | 54 | M22X1.5 | 84 | 48 | 111 | 0.3 | 15 | 57 | 68 | 480 |

| SA25T/K | 25 | 31 | 42.85 | 22 | 60 | M24X2 | 94 | 55 | 124 | 0.3 | 15 | 68 | 85 | 640 |

| SA28T/K | 28 | 35 | 47.6 | 24 | 66 | M27X2 | 103 | 62 | 136 | 0.3 | 15 | 86 | 107 | 800 |

| SA30T/K | 30 | 37 | 50.8 | 25 | 71 | M30X2 | 110 | 66 | 145 | 0.3 | 17 | 88 | 114 | 1100 |

| SA35TK | 35 | 43 | 57.1 | 28 | 81 | M36X3 | 140 | 85 | 180.5 | 0.3 | 16 | 1640 | ||

SA…PK Series

| Part No: | Dimension | Torque Kgf/cm | Load Rating(KN) | Weight | |||||||||||

| d | d1 | B | a | C1 | d2 | G | h1 | L4 | L3 | Cr | Cor | g | |||

| SA3PK | NOS-3 | 3 | 6.8 | 6 | 11 | 4.5 | 12 | M3x0.5 | 27 | 33 | 15 | 0.2~3.5 | 6 | ||

| SA4PK | NOS-4 | 4 | 7.6 | 7 | 12 | 5.3 | 14 | M4x0.7 | 30 | 37 | 17 | 0.2~3.5 | 10 | ||

| SA5PK | NOS-5 | 5 | 7.7 | 8 | 12 | 6 | 16 | M5x0.8 | 33 | 41 | 20 | 0.2~3.5 | 5.7 | 6 | 12 |

| SA6PK | NOS-6 | 6 | 9 | 9 | 10 | 6.8 | 18 | M6x1 | 36 | 45 | 22 | 0.2~3.5 | 7.2 | 7.65 | 19 |

| SA8PK | NOS-8 | 8 | 10.4 | 12 | 12 | 9 | 22 | M8x1.25 | 42 | 53 | 25 | 0.2~3.5 | 11.6 | 12.9 | 32 |

| SA10PK | NOS-10 | 10 | 12.9 | 14 | 12 | 10.5 | 26 | M10x1.5 | 48 | 61 | 29 | 0.2~3.5 | 14.5 | 18 | 54 |

| SA12PK | NOS-12 | 12 | 15.4 | 16 | 12 | 12 | 30 | M12x1.75 | 54 | 69 | 33 | 0.2~3.5 | 17 | 24 | 85 |

| SA14PK | NOS-14 | 14 | 16.9 | 19 | 14 | 13.5 | 34 | M14x2 | 60 | 77 | 36 | 0.2~3.5 | 24 | 31 | 126 |

| SA16PK | NOS-16 | 16 | 19.4 | 21 | 13 | 15 | 38 | M16x2 | 66 | 85 | 40 | 0.2~3.5 | 28.5 | 39 | 185 |

| SA18PK | NOS-18 | 18 | 21.9 | 23 | 14 | 17 | 42 | M18x1.5 | 72 | 93 | 44 | 0.2~3.5 | 42.5 | 47.5 | 258 |

| SA20PK | NOS-20 | 20 | 24.4 | 25 | 12 | 18 | 46 | M20x1.5 | 78 | 101 | 47 | 0.2~3.5 | 42.5 | 57 | 340 |

| SA22PK | NOS-22 | 22 | 25.8 | 28 | 13 | 20 | 50 | M22x1.5 | 84 | 109 | 51 | 0.2~3.5 | 57 | 68 | 435 |

| SA25PK | NOS-25 | 25 | 29.6 | 31 | 14 | 22 | 56 | M24x2 | 94 | 122 | 57 | 0.2~3.5 | 68 | 85 | 730 |

| SA28PK | NOS-28 | 28 | 32.3 | 35 | 16 | 26 | 66 | M27x2 | 110 | 143 | 66 | 0.2~3.5 | 1000 | ||

| SA30PK | NOS-30 | 30 | 34.8 | 37 | 16 | 26 | 66 | M30x2 | 110 | 143 | 66 | 0.2~3.5 | 1320 | ||

OUR WORKSHOP

OUR FACTORY

PACKAGING

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Rolling Element: | Single Row |

|---|---|

| Structure: | Rod End |

| Material: | Bearing Steel |

| Samples: |

US$ 8/Set

1 Set(Min.Order) | Order Sample |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Recent Advancements in Rod End Bearing Technology

Advancements in rod end bearing technology have led to improved performance and durability. Here are some insights into recent developments:

1. Enhanced Materials: Manufacturers are using advanced materials, including high-strength alloys and composites, to create rod end bearings that offer increased load-carrying capacity and improved corrosion resistance. These materials contribute to longer bearing life and better performance in challenging environments.

2. Sealing and Shielding: Innovations in sealing and shielding technologies have improved the protection of rod end bearings from contaminants, moisture, and harsh environmental conditions. These advancements extend maintenance intervals and increase bearing reliability.

3. Lubrication: Self-lubricating rod end bearings have become more prevalent, reducing the need for frequent manual lubrication. These bearings are designed to provide consistent and long-lasting lubrication, resulting in reduced maintenance requirements and longer service life.

4. 3D Modeling and Simulation: Manufacturers are increasingly using 3D modeling and simulation techniques to optimize rod end bearing designs. This allows for the creation of bearings that can handle higher loads and offer superior wear resistance while maintaining compact dimensions.

5. Customization: The ability to customize rod end bearings to specific application requirements has improved. This includes options for different thread types, materials, and sizes. Customization ensures that the bearing can meet the exact needs of the equipment it serves.

6. Environmental Sustainability: Some recent advancements focus on producing rod end bearings in an environmentally sustainable manner. Manufacturers are exploring eco-friendly materials and production processes to reduce the environmental impact of bearing manufacturing.

7. IoT Integration: In industrial applications, the integration of Internet of Things (IoT) technology allows for real-time monitoring and predictive maintenance of rod end bearings. Sensors and data analytics help detect early signs of wear or damage, optimizing maintenance schedules and minimizing downtime.

These recent advancements in rod end bearing technology have collectively improved the reliability, durability, and performance of these components in various mechanical systems. As technology continues to evolve, rod end bearings are expected to play an even more critical role in enhancing the efficiency and longevity of machinery and equipment.

Challenges and Solutions in Managing Load and Misalignment in Rod End Bearings

Rod end bearings often face challenges related to load capacity and misalignment in various applications. Here are the common challenges and solutions:

1. Radial and Axial Loads:

Challenge: Rod end bearings need to handle both radial and axial loads simultaneously in many applications.

Solution: Select rod end bearings with appropriate load ratings and materials to ensure they can withstand the expected loads. Also, proper maintenance and lubrication are essential for maximizing load-carrying capacity.

2. Misalignment:

Challenge: Misalignment can cause premature wear and reduced bearing lifespan.

Solution: Use self-aligning rod end bearings or incorporate spherical plain bearings to compensate for misalignment. Regular inspection and maintenance to correct any alignment issues are crucial.

3. Corrosion and Contaminants:

Challenge: Exposure to moisture, chemicals, and contaminants can lead to corrosion and damage.

Solution: Choose rod end bearings with suitable protective coatings or seals, such as PTFE liners or rubber boots, to prevent contaminants from entering. Stainless steel bearings offer enhanced corrosion resistance.

4. Lubrication:

Challenge: Inadequate lubrication can result in increased friction, overheating, and premature failure.

Solution: Follow the manufacturer’s lubrication recommendations and maintenance schedules. Proper lubrication ensures smooth operation and extends bearing life.

5. Shock and Impact Loads:

Challenge: Applications with frequent shock and impact loads can subject rod end bearings to excessive stress.

Solution: Choose rod end bearings with robust construction and materials to withstand shock loads. Regular inspections are necessary to detect early signs of damage.

By addressing these challenges with appropriate solutions, rod end bearings can perform optimally and provide long-lasting service in a wide range of applications.

Factors to Consider When Selecting a Rod End Bearing for a Specific Application

Choosing the right rod end bearing for a specific application is crucial to ensure optimal performance and longevity. Several factors should be taken into account during the selection process:

1. Load Capacity: Consider the magnitude and type of loads the bearing will need to support. Determine whether it will experience radial, axial, or a combination of loads. Select a rod end bearing with the appropriate load capacity rating to handle these loads.

2. Misalignment: Evaluate the degree of angular misalignment that may occur in the application. Some rod end bearings are designed to compensate for misalignment better than others. Choose a bearing that can accommodate the expected misalignment without compromising performance.

3. Environment: Take into account the operating environment. Consider factors like temperature, humidity, chemical exposure, and the presence of contaminants. Select a rod end bearing with suitable materials and protective features to withstand these conditions.

4. Lubrication: Proper lubrication is essential for the longevity and smooth operation of rod end bearings. Determine the lubrication method and frequency required for the application. Some rod end bearings come with built-in lubrication provisions or self-lubricating materials.

5. Thread Type and Size: The threaded shank of the rod end bearing should match the components it connects to. Consider the thread size and type (e.g., right-hand or left-hand threads) to ensure compatibility with your application.

6. Corrosion Resistance: If the application is in a corrosive environment, select a rod end bearing with corrosion-resistant materials or coatings. This is especially important in marine, chemical, or industrial settings.

7. Size and Weight Constraints: Ensure that the chosen rod end bearing fits within the space and weight limitations of the application. Measure the available space and consider weight restrictions when making your selection.

8. Operating Speed: Take into account the rotational or oscillatory speed of the bearing. Some rod end bearings are designed for high-speed applications, while others are better suited for low-speed or static applications.

9. Regulatory Compliance: In some industries, specific standards or regulations may apply to components like rod end bearings. Ensure that the selected bearing complies with any relevant industry standards or requirements.

10. Budget Constraints: While quality is essential, consider your budget constraints. Different rod end bearings come with varying price points. Choose a bearing that provides the necessary performance without exceeding your budget.

By carefully considering these factors, you can select the most suitable rod end bearing for your specific application, ensuring reliable and efficient operation.

editor by CX 2024-05-14

China OEM High Precision Spherical Plain Bearing with Internal Thread Si16tk Si16t/K Fish Eye Bearing Rod End Joint Bearing for Gear Box with Best Sales

Product Description

0.2~3.5 SI…TK Series (PHS Series)Rod Ends is belong to maintenance-free Rod Ends bearing. The rod end body is equipped with a left-hand or right-hand external thread. The rod end body is formed by extrusion and the surface of the rod end body is galvanized. And The outer sphere is lined with PTFE synthetic material.

PRODUCTS CATALOGUE

SI…T/K Series

| Part No: | Dimension | Torque Kgf/cm | Load Rating(KN) | Weight | ||||||||||||||

| d | B | d1 | a | C1 | d2 | G | h1 | L3 | L4 | L5 | W | d4 | d5 | Cr | Cor | g | ||

| SI5T/K | 5 | 8 | 11.11 | 13 | 6 | 18 | M5x0.8 | 27 | 10 | 36 | 4 | 9 | 9 | 11 | 0.2~3.5 | 5.7 | 6 | 16 |

| SI6T/K | 6 | 9 | 12.7 | 13 | 6.75 | 20 | M6X1.0 | 30 | 12 | 40 | 5 | 11 | 10 | 13 | 0.2~3.5 | 7.2 | 7.65 | 22 |

| SI8T/K | 8 | 12 | 15.875 | 14 | 9 | 24 | M8X1.25 | 36 | 16 | 48 | 5 | 14 | 12.5 | 16 | 0.2~3.5 | 11.6 | 12.9 | 47 |

| SI10T/K | 10 | 14 | 19.05 | 13 | 10.5 | 28 | M10X1.5 | 43 | 20 | 57 | 6.5 | 17 | 15 | 19 | 0.2~3.5 | 14.5 | 18 | 77 |

| SI10T/K-1 | 10 | 14 | 19.05 | 13 | 10.5 | 28 | M10X1.25 | 43 | 20 | 57 | 6.5 | 17 | 15 | 19 | 0.2~3.5 | 14.5 | 18 | 77 |

| SI12T/K | 12 | 16 | 22.225 | 13 | 12 | 32 | M12X1.75 | 50 | 22 | 66 | 6.5 | 19 | 17.5 | 22 | 0.2~3.5 | 17 | 24 | 100 |

| SI12T/K-1 | 12 | 16 | 22.225 | 13 | 12 | 32 | M12X1.25 | 50 | 22 | 66 | 6.5 | 19 | 17.5 | 22 | 0.2~3.5 | 17 | 24 | 100 |

| SI14T/K | 14 | 19 | 25.4 | 16 | 13.5 | 38 | M14X2.0 | 57 | 25 | 75 | 8 | 22 | 20 | 25 | 0.2~3.5 | 24 | 31 | 160 |

| SI14T/K-1 | 14 | 19 | 25.4 | 16 | 13.5 | 38 | M14X1.5 | 57 | 25 | 75 | 8 | 22 | 20 | 25 | 0.2~3.5 | 24 | 31 | 160 |

| SI16T/K | 16 | 21 | 28.575 | 15 | 15 | 42 | M16X2.0 | 64 | 28 | 85 | 8 | 22 | 22 | 27 | 0.2~3.5 | 28.5 | 39 | 220 |

| SI16T/K-1 | 16 | 21 | 28.575 | 15 | 15 | 42 | M16X1.5 | 64 | 28 | 85 | 8 | 22 | 22 | 27 | 0.2~3.5 | 28.5 | 39 | 220 |

| SI18T/K | 18 | 23 | 31.75 | 15 | 16.5 | 44 | M18X1.5 | 71 | 32 | 93 | 10 | 27 | 25 | 31 | 0.2~3.5 | 42.5 | 47.5 | 320 |

| SI20T/K | 20 | 25 | 34.925 | 14 | 18 | 50 | M20X1.5 | 77 | 33 | 102 | 10 | 30 | 27.5 | 34 | 0.2~3.5 | 42.5 | 57 | 420 |

| SI22T/K | 22 | 28 | 38.1 | 15 | 20 | 54 | M22X1.5 | 84 | 37 | 111 | 12 | 32 | 30 | 38 | 0.2~3.5 | 57 | 68 | 540 |

| SI25T/K | 25 | 31 | 42.85 | 15 | 22 | 60 | M24X2 | 94 | 42 | 124 | 12 | 36 | 33.5 | 42 | 0.2~3.5 | 68 | 85 | 720 |

| SI28T/K | 28 | 35 | 47.6 | 15 | 24 | 66 | M27X2 | 103 | 51 | 136 | 14 | 41 | 37 | 46 | 0.2~3.5 | 86 | 107 | 820 |

| SI30T/K | 30 | 37 | 50.8 | 17 | 25 | 70 | M30X2 | 110 | 51 | 145 | 15 | 41 | 40 | 50 | 0.2~3.5 | 88 | 114 | 1100 |

| SI30T/K-1 | 30 | 37 | 50.8 | 17 | 25 | 70 | M27X2 | 110 | 51 | 145 | 15 | 41 | 40 | 50 | 0.2~3.5 | 88 | 114 | 1100 |

| SI35T/K | 35 | 43 | 57.10 | 16 | 28 | 81 | M36X2 | 125 | 56 | 166 | 17 | 50 | 46 | 58 | 0.2~3.5 | 1600 | ||

SA…T/K Series

| Part No: | Dimension | Load Rating(KN) | Weight | |||||||||||

| d | B | dk | C1 | d2 | G | h | L1 | L2 | R1S | a | Cr | Cor | g | |

| SA5T/K | 5 | 8 | 11.11 | 6 | 18 | M5X0.8 | 33 | 19 | 42 | 0.3 | 13 | 5.7 | 6 | 13 |

| SA6T/K | 6 | 9 | 12.7 | 6.75 | 20 | M6X1.0 | 36 | 21 | 46 | 0.3 | 13 | 7.2 | 7.65 | 20 |

| SA8T/K | 8 | 12 | 15.875 | 9 | 24 | M8X1.25 | 42 | 25 | 54 | 0.3 | 14 | 11.6 | 12.9 | 38 |

| SA10T/K | 10 | 14 | 19.05 | 10.5 | 28 | M10X1.5 | 48 | 28 | 62 | 0.3 | 13 | 14.5 | 18 | 55 |

| SA12T/K | 12 | 16 | 22.225 | 12 | 32 | M12X1.75 | 54 | 32 | 70 | 0.3 | 13 | 17 | 24 | 850 |

| SA14T/K | 14 | 19 | 25.4 | 13.5 | 38 | M14X2.0 | 60 | 36 | 78 | 0.3 | 16 | 24 | 31 | 140 |

| SA16T/K | 16 | 21 | 8.575 | 15 | 42 | M16X2.0 | 66 | 37 | 87 | 0.3 | 15 | 28.5 | 39 | 210 |

| SA18T/K | 18 | 23 | 31.75 | 16.5 | 46 | M18X1.5 | 72 | 41 | 94 | 0.3 | 15 | 42.5 | 47.5 | 290 |

| SA20T/K | 20 | 25 | 34.925 | 18 | 50 | M20X1.5 | 78 | 45 | 103 | 0.3 | 14 | 42.5 | 57 | 380 |

| SA22T/K | 22 | 28 | 38.1 | 20 | 54 | M22X1.5 | 84 | 48 | 111 | 0.3 | 15 | 57 | 68 | 480 |

| SA25T/K | 25 | 31 | 42.85 | 22 | 60 | M24X2 | 94 | 55 | 124 | 0.3 | 15 | 68 | 85 | 640 |

| SA28T/K | 28 | 35 | 47.6 | 24 | 66 | M27X2 | 103 | 62 | 136 | 0.3 | 15 | 86 | 107 | 800 |

| SA30T/K | 30 | 37 | 50.8 | 25 | 71 | M30X2 | 110 | 66 | 145 | 0.3 | 17 | 88 | 114 | 1100 |

| SA35TK | 35 | 43 | 57.1 | 28 | 81 | M36X3 | 140 | 85 | 180.5 | 0.3 | 16 | 1640 | ||

SA…PK Series

| Part No: | Dimension | Torque Kgf/cm | Load Rating(KN) | Weight | |||||||||||

| d | d1 | B | a | C1 | d2 | G | h1 | L4 | L3 | Cr | Cor | g | |||

| SA3PK | NOS-3 | 3 | 6.8 | 6 | 11 | 4.5 | 12 | M3x0.5 | 27 | 33 | 15 | 0.2~3.5 | 6 | ||

| SA4PK | NOS-4 | 4 | 7.6 | 7 | 12 | 5.3 | 14 | M4x0.7 | 30 | 37 | 17 | 0.2~3.5 | 10 | ||

| SA5PK | NOS-5 | 5 | 7.7 | 8 | 12 | 6 | 16 | M5x0.8 | 33 | 41 | 20 | 0.2~3.5 | 5.7 | 6 | 12 |

| SA6PK | NOS-6 | 6 | 9 | 9 | 10 | 6.8 | 18 | M6x1 | 36 | 45 | 22 | 0.2~3.5 | 7.2 | 7.65 | 19 |

| SA8PK | NOS-8 | 8 | 10.4 | 12 | 12 | 9 | 22 | M8x1.25 | 42 | 53 | 25 | 0.2~3.5 | 11.6 | 12.9 | 32 |

| SA10PK | NOS-10 | 10 | 12.9 | 14 | 12 | 10.5 | 26 | M10x1.5 | 48 | 61 | 29 | 0.2~3.5 | 14.5 | 18 | 54 |

| SA12PK | NOS-12 | 12 | 15.4 | 16 | 12 | 12 | 30 | M12x1.75 | 54 | 69 | 33 | 0.2~3.5 | 17 | 24 | 85 |

| SA14PK | NOS-14 | 14 | 16.9 | 19 | 14 | 13.5 | 34 | M14x2 | 60 | 77 | 36 | 0.2~3.5 | 24 | 31 | 126 |

| SA16PK | NOS-16 | 16 | 19.4 | 21 | 13 | 15 | 38 | M16x2 | 66 | 85 | 40 | 0.2~3.5 | 28.5 | 39 | 185 |

| SA18PK | NOS-18 | 18 | 21.9 | 23 | 14 | 17 | 42 | M18x1.5 | 72 | 93 | 44 | 0.2~3.5 | 42.5 | 47.5 | 258 |

| SA20PK | NOS-20 | 20 | 24.4 | 25 | 12 | 18 | 46 | M20x1.5 | 78 | 101 | 47 | 0.2~3.5 | 42.5 | 57 | 340 |

| SA22PK | NOS-22 | 22 | 25.8 | 28 | 13 | 20 | 50 | M22x1.5 | 84 | 109 | 51 | 0.2~3.5 | 57 | 68 | 435 |

| SA25PK | NOS-25 | 25 | 29.6 | 31 | 14 | 22 | 56 | M24x2 | 94 | 122 | 57 | 0.2~3.5 | 68 | 85 | 730 |

| SA28PK | NOS-28 | 28 | 32.3 | 35 | 16 | 26 | 66 | M27x2 | 110 | 143 | 66 | 0.2~3.5 | 1000 | ||

| SA30PK | NOS-30 | 30 | 34.8 | 37 | 16 | 26 | 66 | M30x2 | 110 | 143 | 66 | 0.2~3.5 | 1320 | ||

OUR WORKSHOP

OUR FACTORY

PACKAGING

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Rolling Element: | Single Row |

|---|---|

| Structure: | Rod End |

| Material: | Bearing Steel |

| Samples: |

US$ 5/Set

1 Set(Min.Order) | Order Sample |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Recent Advancements in Rod End Bearing Technology

Advancements in rod end bearing technology have led to improved performance and durability. Here are some insights into recent developments:

1. Enhanced Materials: Manufacturers are using advanced materials, including high-strength alloys and composites, to create rod end bearings that offer increased load-carrying capacity and improved corrosion resistance. These materials contribute to longer bearing life and better performance in challenging environments.

2. Sealing and Shielding: Innovations in sealing and shielding technologies have improved the protection of rod end bearings from contaminants, moisture, and harsh environmental conditions. These advancements extend maintenance intervals and increase bearing reliability.

3. Lubrication: Self-lubricating rod end bearings have become more prevalent, reducing the need for frequent manual lubrication. These bearings are designed to provide consistent and long-lasting lubrication, resulting in reduced maintenance requirements and longer service life.

4. 3D Modeling and Simulation: Manufacturers are increasingly using 3D modeling and simulation techniques to optimize rod end bearing designs. This allows for the creation of bearings that can handle higher loads and offer superior wear resistance while maintaining compact dimensions.

5. Customization: The ability to customize rod end bearings to specific application requirements has improved. This includes options for different thread types, materials, and sizes. Customization ensures that the bearing can meet the exact needs of the equipment it serves.

6. Environmental Sustainability: Some recent advancements focus on producing rod end bearings in an environmentally sustainable manner. Manufacturers are exploring eco-friendly materials and production processes to reduce the environmental impact of bearing manufacturing.

7. IoT Integration: In industrial applications, the integration of Internet of Things (IoT) technology allows for real-time monitoring and predictive maintenance of rod end bearings. Sensors and data analytics help detect early signs of wear or damage, optimizing maintenance schedules and minimizing downtime.

These recent advancements in rod end bearing technology have collectively improved the reliability, durability, and performance of these components in various mechanical systems. As technology continues to evolve, rod end bearings are expected to play an even more critical role in enhancing the efficiency and longevity of machinery and equipment.

Challenges and Solutions in Managing Load and Misalignment in Rod End Bearings

Rod end bearings often face challenges related to load capacity and misalignment in various applications. Here are the common challenges and solutions:

1. Radial and Axial Loads:

Challenge: Rod end bearings need to handle both radial and axial loads simultaneously in many applications.

Solution: Select rod end bearings with appropriate load ratings and materials to ensure they can withstand the expected loads. Also, proper maintenance and lubrication are essential for maximizing load-carrying capacity.

2. Misalignment:

Challenge: Misalignment can cause premature wear and reduced bearing lifespan.

Solution: Use self-aligning rod end bearings or incorporate spherical plain bearings to compensate for misalignment. Regular inspection and maintenance to correct any alignment issues are crucial.

3. Corrosion and Contaminants:

Challenge: Exposure to moisture, chemicals, and contaminants can lead to corrosion and damage.

Solution: Choose rod end bearings with suitable protective coatings or seals, such as PTFE liners or rubber boots, to prevent contaminants from entering. Stainless steel bearings offer enhanced corrosion resistance.

4. Lubrication:

Challenge: Inadequate lubrication can result in increased friction, overheating, and premature failure.

Solution: Follow the manufacturer’s lubrication recommendations and maintenance schedules. Proper lubrication ensures smooth operation and extends bearing life.

5. Shock and Impact Loads:

Challenge: Applications with frequent shock and impact loads can subject rod end bearings to excessive stress.

Solution: Choose rod end bearings with robust construction and materials to withstand shock loads. Regular inspections are necessary to detect early signs of damage.

By addressing these challenges with appropriate solutions, rod end bearings can perform optimally and provide long-lasting service in a wide range of applications.

Design Principles and Functions of Rod End Bearings

Rod end bearings, also known as heim joints or rose joints, are essential components in various mechanical applications, where articulation and precise control of movement are required. These bearings are designed with specific principles and functions in mind:

Design Principles:

Rod end bearings consist of a spherical plain bearing, also known as a spherical plain bushing, within a housing. The design principles are as follows:

- Spherical Plain Bearing: The heart of a rod end bearing is a spherical plain bearing. This bearing allows the inner ring to tilt and rotate in multiple directions. It consists of an inner and outer ring with a sliding layer of material in between, often made from self-lubricating materials.

- Housing: The spherical plain bearing is housed within a protective casing, typically made of metal or other durable materials. The housing provides structural support and retains the bearing components.

- Threaded Shank: The outer part of the housing is often shaped as a threaded shank, allowing for easy attachment to various mechanical components, such as linkages or control arms.

- Lubrication Fittings: Many rod end bearings have provisions for lubrication fittings to ensure smooth articulation and reduce friction.

Functions:

Rod end bearings serve several crucial functions in mechanical systems:

- Articulation: Rod end bearings provide articulation, enabling components to pivot, swivel, and move in multiple directions. This function is vital in applications requiring flexibility and control over movement.

- Angular Misalignment Compensation: They can compensate for both static and dynamic angular misalignment. This is particularly useful in situations where components may not align perfectly due to varying factors like vibration or assembly tolerances.

- Load Transmission: Rod end bearings can transmit static and dynamic loads, making them suitable for applications involving force or load transfer. They are used in machinery and equipment where precise control of loads is essential.

- Precision Movement: These bearings provide precise control and movement, making them suitable for applications where accurate positioning of mechanical components is critical. This includes industries like aerospace and robotics.

- Corrosion Resistance: Many rod end bearings are designed with corrosion-resistant materials or coatings, making them suitable for use in harsh environments, such as marine and industrial settings.

- Durability: Rod end bearings are engineered for durability, allowing them to withstand challenging conditions and heavy-duty use. This ensures their reliability and longevity in demanding applications.

- Versatility: Rod end bearings are versatile components used across various industries, including automotive, aerospace, industrial machinery, and marine applications. Their adaptability and reliability make them valuable to engineers and designers.

These design principles and functions of rod end bearings make them indispensable in a wide range of mechanical systems where articulation, load-bearing capacity, and precise control are required.

editor by CX 2024-04-03

China Best Sales High Precision Rod End Bearing Fish Eye Bearing SA16t/K SA16tk Left & Right Hand Thread M16 Joint Bearing SA16t/K with Male Thread Steel Bearing for Gear Box bearing assembly

Product Description

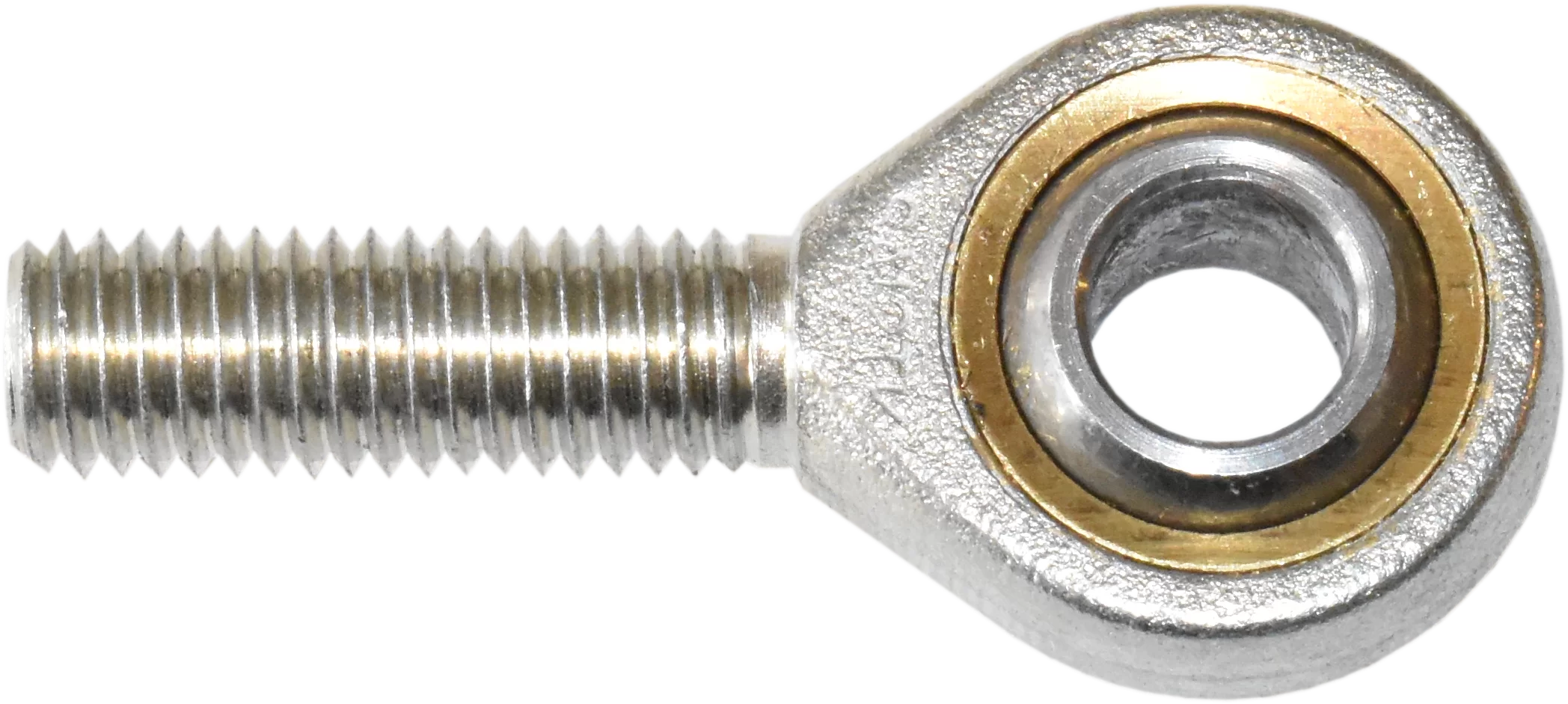

SA…TK Series Rod Ends is belong to maintenance-free Rod Ends bearing. The rod end body is equipped with a left-hand or right-hand external thread. The rod end body is formed by extrusion and the surface of the rod end body is galvanized. And The outer sphere is lined with PTFE synthetic material.

PRODUCTS CATALOGUE

| Part No: | Dimension | Load Rating(KN) | Weight | |||||||||||

| d | B | dk | C1 | d2 | G | h | L1 | L2 | R1S | a | Cr | Cor | g | |

| SA5T/K | 5 | 8 | 11.11 | 6 | 18 | M5X0.8 | 33 | 19 | 42 | 0.3 | 13 | 5.7 | 6 | 13 |

| SA6T/K | 6 | 9 | 12.7 | 6.75 | 20 | M6X1.0 | 36 | 21 | 46 | 0.3 | 13 | 7.2 | 7.65 | 20 |

| SA8T/K | 8 | 12 | 15.875 | 9 | 24 | M8X1.25 | 42 | 25 | 54 | 0.3 | 14 | 11.6 | 12.9 | 38 |

| SA10T/K | 10 | 14 | 19.05 | 10.5 | 28 | M10X1.5 | 48 | 28 | 62 | 0.3 | 13 | 14.5 | 18 | 55 |

| SA12T/K | 12 | 16 | 22.225 | 12 | 32 | M12X1.75 | 54 | 32 | 70 | 0.3 | 13 | 17 | 24 | 850 |

| SA14T/K | 14 | 19 | 25.4 | 13.5 | 38 | M14X2.0 | 60 | 36 | 78 | 0.3 | 16 | 24 | 31 | 140 |

| SA16T/K | 16 | 21 | 8.575 | 15 | 42 | M16X2.0 | 66 | 37 | 87 | 0.3 | 15 | 28.5 | 39 | 210 |

| SA18T/K | 18 | 23 | 31.75 | 16.5 | 46 | M18X1.5 | 72 | 41 | 94 | 0.3 | 15 | 42.5 | 47.5 | 290 |

| SA20T/K | 20 | 25 | 34.925 | 18 | 50 | M20X1.5 | 78 | 45 | 103 | 0.3 | 14 | 42.5 | 57 | 380 |

| SA22T/K | 22 | 28 | 38.1 | 20 | 54 | M22X1.5 | 84 | 48 | 111 | 0.3 | 15 | 57 | 68 | 480 |

| SA25T/K | 25 | 31 | 42.85 | 22 | 60 | M24X2 | 94 | 55 | 124 | 0.3 | 15 | 68 | 85 | 640 |

| SA28T/K | 28 | 35 | 47.6 | 24 | 66 | M27X2 | 103 | 62 | 136 | 0.3 | 15 | 86 | 107 | 800 |

| SA30T/K | 30 | 37 | 50.8 | 25 | 71 | M30X2 | 110 | 66 | 145 | 0.3 | 17 | 88 | 114 | 1100 |

| SA35TK | 35 | 43 | 57.1 | 28 | 81 | M36X3 | 140 | 85 | 180.5 | 0.3 | 16 | 1640 | ||

SA…PK Series

| Part No: | Dimension | Torque Kgf/cm | Load Rating(KN) | Weight | |||||||||||

| d | d1 | B | a | C1 | d2 | G | h1 | L4 | L3 | Cr | Cor | g | |||

| SA3PK | NOS-3 | 3 | 6.8 | 6 | 11 | 4.5 | 12 | M3x0.5 | 27 | 33 | 15 | 0.2~3.5 | 6 | ||

| SA4PK | NOS-4 | 4 | 7.6 | 7 | 12 | 5.3 | 14 | M4x0.7 | 30 | 37 | 17 | 0.2~3.5 | 10 | ||

| SA5PK | NOS-5 | 5 | 7.7 | 8 | 12 | 6 | 16 | M5x0.8 | 33 | 41 | 20 | 0.2~3.5 | 5.7 | 6 | 12 |

| SA6PK | NOS-6 | 6 | 9 | 9 | 10 | 6.8 | 18 | M6x1 | 36 | 45 | 22 | 0.2~3.5 | 7.2 | 7.65 | 19 |

| SA8PK | NOS-8 | 8 | 10.4 | 12 | 12 | 9 | 22 | M8x1.25 | 42 | 53 | 25 | 0.2~3.5 | 11.6 | 12.9 | 32 |

| SA10PK | NOS-10 | 10 | 12.9 | 14 | 12 | 10.5 | 26 | M10x1.5 | 48 | 61 | 29 | 0.2~3.5 | 14.5 | 18 | 54 |

| SA12PK | NOS-12 | 12 | 15.4 | 16 | 12 | 12 | 30 | M12x1.75 | 54 | 69 | 33 | 0.2~3.5 | 17 | 24 | 85 |

| SA14PK | NOS-14 | 14 | 16.9 | 19 | 14 | 13.5 | 34 | M14x2 | 60 | 77 | 36 | 0.2~3.5 | 24 | 31 | 126 |

| SA16PK | NOS-16 | 16 | 19.4 | 21 | 13 | 15 | 38 | M16x2 | 66 | 85 | 40 | 0.2~3.5 | 28.5 | 39 | 185 |

| SA18PK | NOS-18 | 18 | 21.9 | 23 | 14 | 17 | 42 | M18x1.5 | 72 | 93 | 44 | 0.2~3.5 | 42.5 | 47.5 | 258 |

| SA20PK | NOS-20 | 20 | 24.4 | 25 | 12 | 18 | 46 | M20x1.5 | 78 | 101 | 47 | 0.2~3.5 | 42.5 | 57 | 340 |

| SA22PK | NOS-22 | 22 | 25.8 | 28 | 13 | 20 | 50 | M22x1.5 | 84 | 109 | 51 | 0.2~3.5 | 57 | 68 | 435 |

| SA25PK | NOS-25 | 25 | 29.6 | 31 | 14 | 22 | 56 | M24x2 | 94 | 122 | 57 | 0.2~3.5 | 68 | 85 | 730 |

| SA28PK | NOS-28 | 28 | 32.3 | 35 | 16 | 26 | 66 | M27x2 | 110 | 143 | 66 | 0.2~3.5 | 1000 | ||

| SA30PK | NOS-30 | 30 | 34.8 | 37 | 16 | 26 | 66 | M30x2 | 110 | 143 | 66 | 0.2~3.5 | 1320 | ||

OUR WORKSHOP

OUR FACTORY

PACKAGING

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Rolling Element: | Single Row |

|---|---|

| Structure: | Rod End |

| Material: | Bearing Steel |

| Samples: |

US$ 5/Set

1 Set(Min.Order) | Order Sample |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Selecting Size and Thread Type for Rod End Bearings

When choosing the appropriate size and thread type for a rod end bearing, several considerations are important:

1. Load Requirements: Determine the expected loads the rod end bearing will need to support. Choose a size and material that can handle these loads without deformation or premature wear.

2. Thread Direction: Consider whether you need left-hand or right-hand threads. This depends on the specific application and the direction in which the rod end bearing will be subject to forces or adjustments.

3. Thread Size and Pitch: Select the thread size and pitch that match the mating components or the mounting point. Ensure compatibility to avoid threading issues during installation.

4. Environmental Conditions: Consider the operating environment. If the rod end bearing will be exposed to moisture, chemicals, or extreme temperatures, choose a material and thread type that can withstand these conditions without corrosion or degradation.

5. Lubrication: Evaluate the lubrication method. Some rod end bearings have built-in lubrication features, while others require external lubrication. Ensure that the selected bearing and thread type align with your lubrication approach.

6. Misalignment Requirements: If the application involves misalignment, select a rod end bearing with appropriate articulation capabilities, which may require specific size and thread choices to allow for the necessary movement.

7. Compatibility: Ensure that the rod end bearing’s size and thread type are compatible with the connecting components, such as linkages, control arms, or push/pull rods.

8. Adjustability: In applications where adjustability is required, consider rod end bearings with male and female threads to allow for fine-tuning and alignment.

9. Regulations and Standards: Check if there are industry or safety regulations that dictate specific size or thread requirements for your application.

10. Maintenance: Consider ease of maintenance. Some rod end bearings have features that facilitate inspection and lubrication, which can be essential for extending their lifespan.

11. Cost and Availability: Finally, factor in the cost and availability of the chosen rod end bearing size and thread type. Ensure it fits within your budget and can be readily sourced when needed.

By carefully evaluating these considerations, you can select the most suitable rod end bearing size and thread type for your specific application, ensuring optimal performance and longevity.

Contribution of Rod End Bearings to Smooth Movement in Automotive Control Systems

Rod end bearings play a crucial role in ensuring the smooth movement of control systems in various automotive applications. Here’s how they contribute:

1. Steering Systems:

Rod end bearings are used in steering linkages and tie rod ends. They provide the necessary articulation and pivoting to allow the front wheels to turn smoothly, enabling precise steering control. The low friction and high load-bearing capacity of rod end bearings contribute to responsive and accurate steering in both manual and power steering systems.

2. Suspension Systems:

In suspension systems, rod end bearings are used in components like control arms and stabilizer links. They allow for controlled movement of the suspension, ensuring that the vehicle’s wheels maintain optimal contact with the road surface. This contributes to a smoother and more comfortable ride, improved handling, and better traction, especially when driving over uneven or bumpy terrain.

3. Throttle and Accelerator Linkages:

Rod end bearings are employed in throttle and accelerator linkages, where they assist in transmitting pedal inputs to the engine’s throttle body. The smooth articulation provided by rod end bearings ensures that drivers can easily modulate engine power, contributing to smooth acceleration and deceleration.

4. Gear Shift Linkages:

In manual transmissions, rod end bearings are used in gear shift linkages. They enable precise and smooth gear changes by allowing for the controlled movement of the shift lever. This ensures that gears engage smoothly, reducing drivetrain shock and vibration.

5. Convertible Roof Mechanisms:

In convertible cars, rod end bearings are used in the mechanisms that operate the folding and unfolding of the convertible roof. The smooth articulation of rod end bearings contributes to the seamless transition between open and closed roof positions, enhancing the overall driving experience.

Overall, rod end bearings are integral components in automotive control systems, ensuring the smooth and precise operation of various critical functions, including steering, suspension, throttle control, gear shifting, and convertible roof movement.

Applications and Industries Using Rod End Bearings

Rod end bearings find application across various industries and serve multiple purposes due to their versatility and design. Common applications and sectors where rod end bearings are used include:

1. Automotive: Rod end bearings are utilized in vehicle suspension systems, steering linkages, and throttle linkages, contributing to precise control and smooth movement.

2. Aerospace: They play a crucial role in aircraft control systems, ensuring reliable and precise movement in critical flight control components.

3. Construction and Heavy Machinery: These bearings are used in heavy equipment like cranes, excavators, and loaders for precise positioning and movement in various parts of the machinery.

4. Manufacturing: In manufacturing machinery, rod end bearings are employed for automation and motion control applications, ensuring accurate and smooth movement in industrial processes.

5. Agricultural Equipment: Farm machinery, such as tractors and combines, use rod end bearings in steering systems, hydraulics, and other mechanical components.

6. Robotics: Rod end bearings are critical in robotic arms and automation systems, facilitating precise movement and control in manufacturing, medical, and other industries.

7. Marine and Offshore: They are used in marine applications, contributing to reliable control and movement in boat steering systems and offshore equipment.

8. Medical Equipment: In medical devices and equipment, rod end bearings ensure precise and smooth movement, making them essential in applications like surgical robots and diagnostic instruments.

9. Racing and Motorsports: Rod end bearings are used in high-performance vehicles for suspension and steering systems, where precise control is paramount.

10. Material Handling: Conveyor systems and material handling equipment benefit from rod end bearings, ensuring efficient movement and transport of goods.

11. Renewable Energy: They play a role in solar tracking systems and wind turbine applications, helping to adjust panel angles and rotor blades for optimal energy capture.

12. Rail and Transportation: In rail systems and transportation equipment, rod end bearings are employed in various components, including doors, brakes, and suspension systems.

13. Sports and Fitness Equipment: In gym equipment and sports machinery, they provide smooth and reliable motion in treadmills, exercise bikes, and more.

Rod end bearings are valued for their ability to provide reliable and precise movement in a wide range of applications, contributing to the efficiency and safety of various industries.

editor by CX 2024-03-28

China Custom Slewing Ring Bearings with Internal Gear bearing air

Product Description

Product Description

Slewing Ring Bearing Definition:

Slewing bearings are large-sized bearings which can accommodate a combined load, i.e., radial loads and tilting moment. They are usually provided with holes for fixing bolts; internal, external or no gear; and lubrication holes and seals, which allow a compact and economical arrangement. In addition, they often enable the elimination of many components necessary in the classical bearing arrangement.

Slewing Ring Bearings are also called slewing rings, slewing bearings, slewing ring bearings, slewing gear, gear, turntable bearings and rotary bearing

Slew Ring Bing Specifications:

|

Product Name |

High Precision Slewing Bearing |

|

Material |

Chrome Steel |

|

Operating Temperature |

-40°C ~ +50°C |

|

Heat treatment |

Quenching and tempering, Raceway induction quenching |

|

Standard |

EN 15714 2.2; EN 15714 3.1.B ; EN15714 3.1.C |

|

Features |

Four Point Contact |

|

Application |

Crane, Excavator, all kinds of machine |

Slew Ring Bing Types:

1. 4 point contact ball slewing ring bearings

2. double row ball 4 point contact slewing ring bearings(same diameter ball; different diameter ball)

3. cross roller slewing ring bearings

4. triple row cylindrical roller combined slewing ring bearings

5. ball roller combined slewing ring bearings

6. light flanged slewing ring bearings

Slew Ring Bing Applications:

Slewing ring bearings are widely used in industry and known as “the machine joints” Hereunder is the specific slewing bearing applications

1. Construction machinery (e.g. cranes, excavators, loader, scraper)

2. Metallurgical machinery (e.g. for steel plant)

3. Heavy machinery equipments (e.g. mining machinery, concrete machinery)

4. Marine machinery equipment (e.g. vessel, port hoisting machine, port oil transfer equipment, onshore and offshore crane)

5. Light machinery equipments (e.g. paper machine, plastic, rubber machine, weave machine)

6. Wind power generator

7. Military products (e.g. aerospace machinery)

8. Packing machinery

Production Process of Slew Ring Bing:

Forging ring body material ⇒ Rough Lathing ⇒ Raceway heat treatment ⇒ Drilling ⇒ Teeth cutting ⇒ Teeth heat treatment ⇒ Ball hardness inspection ⇒ Assembling ⇒ Finall inspection ⇒ Packaging

Packaging & Shipping

Company Profile

Ruika Slewing bearing is established in 2004 with over 80 patents, FH mainly produce OEM slewing bearing, slew drive, pinion, FH has passed ISO9001-2005, SGS, CAPE etc, FH also accept the service durability test, resist fatigue test, anti-corrosion test and anti-terrible temperature test, which is widely used for Construction machinery, port, AI and new energy industries.

| Standard or Nonstandard: | Standard |

|---|---|

| Feature: | High Speed, Vacuum, Antimagnetic, Cold-Resistant, Corrosion-Resistant, Heat-Resistant |

| Sealing Gland: | Non-Seal |

| Rolling-Element Number: | Multiple-Column |

| Roller Type: | Deep Groove Raceway |

| Material: | Cast Iron |

| Samples: |

US$ 1000/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Advantages of Ball Bearings

What is a ball bearing? A ball bearing is a type of rolling-element bearing that utilizes balls to maintain separation between two bearing races. Its contact angle between the balls and the races helps it reduce friction between the loads. There are several advantages to ball bearings, including their ability to withstand water. Read on to learn more. Here are a few of the benefits. You can use them in your daily life, from your car to your boat.

Ball bearings reduce friction between loads

Ball bearings reduce friction between loads by constraining the relative motion between moving parts. These bearings consist of a ring of small metal balls that reduce friction between moving objects. The name “ball bearing” is derived from the verb “to bear.” The lubricant within the bearing reduces friction between moving particles. In a machine, ball bearings reduce friction between moving parts and improve linear motion around a fixed axis.

These bearings are commonly used to reduce friction between loads in rotating machines. They have two tracks, one fixed to the rotating part and one stationary. The rolling balls of a ball bearing have lower friction than flat surfaces. Because of this, they are useful for bar stool bearings. They reduce friction between surfaces and maintain the separation between bearing races. Hence, minimal surface contact is possible. Ball bearings have the potential to increase the life of machines and reduce energy consumption.

Ball bearings can be as small as a wrist watch or as large as an industrial motor. They function the same way, reducing friction between loads. Among their many uses, ball bearings are essential for everyday operations. Clocks, air conditioners, fans, and automobile axles all use ball bearings. In fact, anything that uses a motor requires ball bearings. It’s no wonder they’re gaining popularity in industries and everyday life.

They support radial and axial loads

Radial ball bearings are used primarily for radial loads, but they also have a capacity for axial load. This load capacity is usually given as a percentage of the radial load rating. Axial load capacity is generally greater for a bearing with a larger difference between the inner and outer ring diameters. The axial load capacity is also affected by the bearing’s raceway depth, with shallow raceways being more suitable for heavier axial loads.

The two main types of axial and radial loads are defined by their orientation. Axial loads apply forces in one direction while radial loads act on the opposite direction. In both cases, the bearing must support the forces that are imposed. Axial loads apply forces to a bearing in a single direction, while radial loads apply forces in both directions. Regardless of the type of load, axial and radial loads should be considered when selecting a bearing for a given application.

Angular and radial ball bearings differ in their materials. Radial ball bearings are made largely of through-hardened materials. They typically have a Rockwell hardness rating of 58 Rc. The raceways and balls of these bearings are made of 440C stainless steel. They may also contain shields and seals. SAE 52100 steel is the most common material for the raceway, while molybdenum steels are excellent for high temperatures.

They have a contact angle between the balls and the races

When comparing axial load bearings with their radial counterparts, the angular contact angle is more important. Axial load bearings, have a contact angle between the balls and the races of 35 degrees. They are suitable for axial loads and a limited radial load. The contact angle of these bearings is a result of the shape of the inner and outer rings. Each rolling element comes into contact with the inner and outer rings only at one point, forming a 30 degree angle with the radial plane. The radial force of the axial load on these bearings is therefore increased by increasing the contact angle between the balls and the races.

This contact angle determines the amount of friction between the balls and the races, and allows angular contact bearings to withstand heavy radial and thrust loads. In addition, the larger the contact angle, the greater the axial load support. Angular contact bearings come in standard imperial (inch) and metric (mm) sizes. The angular contact angle is determined by the free radial play value and the curvature of the inner track.

They are water-resistant

In addition to their water-resistant qualities, corrosion-resistant ball bearings can also protect against the damaging effects of corrosive environments. Generally, standard metals, such as steel, are susceptible to rust, which can significantly reduce their performance and extend the life of parts. However, plastics, stainless steel, and ceramics can provide corrosion-resistant ball bearings. And because these materials are much more durable, they offer other advantages, such as being easy to maintain.

Among the advantages of plastic ball bearings is their high resistance to extreme temperatures, high speeds, and corrosion. Depending on their construction, plastic bearings are often able to resist corrosion and anti-static properties. They’re lightweight and inexpensive compared to steel ball bearings. CZPT Sales Corporation was established in 1987 with a modest turnover of four lacs. As of the last financial year, it has grown to 500 lacs in sales.

Other advantages of water-resistant ball bearings include corrosion resistance, which is a key consideration in many applications. While stainless steel is highly corrosion-resistant, it decreases the bearing’s load-carrying capacity. Also, corrosion-resistant deep groove ball bearings are usually made with a specified internal clearance, which absorbs loss in clearance during mounting and shaft expansion. This factor affects their performance, and if these are compromised, a replacement may be necessary.

They are tough

A few things make ball bearings tough: they’re made of real materials, which means that they have inherent imperfections. Grade-1 balls are made especially for high-stress applications, such as Formula One engines. Grade-3 balls, on the other hand, strike the perfect balance between performance and cost. Ceramic balls, for example, are made to spin at a high rate of 400 RPM, and they’re finished with a mirror finish.

A steel carbon ball bearing is one of the toughest forms of ball bearings available. The material is incredibly strong, but the contact between the balls isn’t the best. Low-carbon steel is best for linear shafting and is usually coated with a polymer to prevent damage. Steel ball bearings with moderate amounts of carbon are tough, durable, and water-resistant. They’re ideal for gears, but their high-carbon steel counterparts are particularly tough and can resist corrosion.

A ceramic ball bearing is another option. This type has steel inner and outer rings but ceramic balls. Ceramic balls can withstand higher temperatures than steel and are also electrically insulating. Ceramic ball bearings also tend to be lighter and are more resistant to wear and tear. They’re also ideal for applications in which grease is not an option, such as in space shuttles. Despite the fact that ceramic ball bearings are tough, they’re still cheaper than steel ball bearings.

They are conductive

You may have heard the term “ball bearing” if you’ve studied introductory physics. What does that mean? Essentially, ball bearings are conductive because of their ability to conduct electricity. This ability is reflected in the charge distribution on the surface of the ball. Positive charges are drawn toward the positive plate, while negative charges are drawn away from the positively charged ball bearing. You may have even seen a ball bearing in action.

However, despite their conductive nature, ball bearings can still become damaged by electrical discharge. A higher voltage can cause the balls to pit, and the raceways to become uneven. These uneven surfaces will first show up as excessive noise, and eventually cause the bearing to malfunction. Fortunately, engineers have found a way to counter this problem: conductive grease. This grease enables current to flow through the ball bearing, preventing both heat and voltage buildup.

The difference between steel and ceramic ball bearings is their density. Steel bearings are more conductive than glass or hybrid ceramics. Steel ball bearings have an even grain structure and are conductive for resonance flow. When moving fast, the air surrounding the steel ball bearing carries resonance from the inner ring to the outer. This makes them ideal for high-speed resonance transfer. In addition to being conductive, glass microbeads are harder and lighter than steel.

They are used in pulley systems

Pulley systems use ball bearings to move the sprocket, which is a wheel that rotates. These bearings are installed on the center mounting hole of the pulley wheel. They protect the entire system from heat, while allowing higher speed and smooth operation. They distribute the weight of the load evenly, minimizing friction and wobbling, and ensure a smooth rotation. Ball bearings are typically made from steel and are installed inside the pulley wheel.

The moment of inertia and bearing friction are measured to within ten percent accuracy. These two variables affect the speed of the pulley system, which can lead to crashes if the weight holders are not balanced. Therefore, ball bearings are used to minimize the chance of such crashes. When you want to know more about ball bearings in pulley systems, here are the advantages they provide.

Another benefit of ball bearings in pulley systems is that they have lower friction than their solid counterparts. In order to reduce friction, however, ball bearings must be made of good materials. Some of the common ball materials are high-quality plastics and stainless steel. Good materials and clever block design are essential to minimizing friction. If you are planning to use ball bearings in your pulley system, check out the following tips and make sure you are choosing the right one for your application.

editor by CX 2023-04-21

China Professional Fy Excavator Bearing Pc158 Slewing Bearings With Worm Gear Motor double row ball bearing

Sort: Slewing Bearing

Relevant Industries: Creating Material Shops, Production Plant, Machinery Restore Shops, Design works , Vitality & Mining

Function: 4 Stage Make contact with

Gear Alternatives: Nongeared

Seals Sort: Rubber seal

Solution Title: Non gear slewing bearing

Dimension: personalized

Shade: vibrant

Materials: 50Mn 42CrMo

Technics: forging,turning

Condition: spherical

Software: excavators, truck cranes, robots, tower cranes

Sample: USD100~3000

OEM: take

MOQ: 1PC

Packaging Specifics: Wood brackets,wooden box

Port: yantian port,HangZhou port,ZheJiang port,HangZhou port

| Solution Name | Slewing bearing |

| Coloration | Vibrant |

| Dimensions | Personalized |

| Substance | 50Mn 42CrMo |

| Floor therapy | N/A |

| Technics | Forging,turning |

| Application | Excavators, truck cranes, US 52 Digital Exhibit Motor Speed Controller Motor Governor Delicate Commence Equipment 220V Ac 6W-400W robots, tower cranes |

| Certification | N/A |

Industrial applications of casing

For rotating and sliding parts, bushings are an important part of the machine. Due to their anti-friction properties and load-carrying capacity, they are an important part of many different industrial processes. Bushings play a vital role in industries such as construction, mining, hydropower, agriculture, transportation, food processing and material handling. To learn more about the benefits of bushings, read on. You’ll be amazed how much they can help your business!

type

When comparing enclosure types, consider the material and how it will be used. Oilite bushings are made of porous material that draws lubricant into the liner and releases it when pressure is applied. These are manufactured using a sintered or powered metal process. Copper and tin are the most commonly used materials for making copper bushings, but there are other types of metal bushings as well.

Another popular type is the plain bearing. This type reduces friction between the rotating shaft and the stationary support element. This type provides support and load bearing while relying on soft metal or plastic for lubrication. Journal bearings are used to support the linear motion of the engine crankshaft in large turbines. They are usually babbitt or hydrodynamic with a liquid film lubricant between the two halves.

The oil-impregnated paper sleeve is made of high-quality kraft insulating paper. These bushings contain two layers of capacitor grading, with the innermost layer electrically connected to the mounting flange. These are mature processes and are widely used in different voltage levels. CZPT Electric (Group) Co., Ltd. provides UHV DC and AC oil-impregnated paper wall bushings for environmental control rooms.

Electrical bushings are used to transmit electricity. These can be transformers, circuit breakers, shunt reactors and power capacitors. The bushing can be built into the bushing or through the bushing. The conductors must be able to carry the rated current without overheating the adjacent insulation. A typical bushing design has a conductor made of copper or aluminum with insulation on all other sides. If the bushing is used in a circuit, the insulation needs to be high enough to prevent any leakage paths.

Voltage and current ratings of electrical bushings. Solid type electrical bushings typically have a center conductor and a porcelain or epoxy insulator. These bushings are used in small distribution transformers and large generator step-up transformers. Their test voltage is typically around 70 kV. Subsequent applications of this bushing may require a lower halfway release limit. However, this is a common type for many other applications.

application

Various industrial applications involve the use of casing. It is an excellent mechanical and chemical material with a wide range of properties. These compounds are also packaged according to national and international standards. Therefore, bushings are used in many different types of machines and equipment. This article will focus on the main industrial applications of casing. This article will also explain what a casing is and what it can do. For more information, click here. Casing application

Among other uses, bushing assemblies are used in aircraft and machinery. For example, a fuel tank of an aircraft may include baffle isolator 40 . The bushing assembly 16 serves as an interface to the fuel tank, allowing electrical current to flow. It can also be used to isolate one component from another. In some cases, bushing assemblies are used to provide a tight fit and reduce electrical resistance, which is important in circuits.

The benefits of casing go beyond reducing energy transmission. They reduce lubrication costs. If two metal parts are in direct contact, lubrication is required. Thus, the bushing reduces the need for lubrication. They also allow parts of the car to move freely. For example, rubber bushings may begin to deteriorate due to high internal temperatures or cold weather. Also, oil can affect their performance.

For example, bushing CTs in oil and gas circuit breakers are used as window current transformers. It consists of a toroidal core and secondary windings. The center conductor of the bushing acts as the single-turn primary of the BCT. By tapping the secondary winding, the ratio between primary and secondary can be changed. This information can be found on the asset nameplate.

Among other uses, bushings are used in diagnostic equipment. These components require precise positioning. Fortunately, air sleeves are perfect for this purpose. Their frictionless operation eliminates the possibility of misalignment. In addition, products based on porous media help minimize noise. A casing manufacturer can advise you on the best product for your equipment. Therefore, if you are looking for replacement bushings for your existing equipment, please feel free to contact Daikin.

Material

Dry ferrule cores were selected for study and examined under an Olympus polarizing microscope (BX51-P). Core slices showing layers of aluminum foil with a distance of approximately 2 cm between adjacent capacitor screens. The aluminum foil surface has a multi-layered structure with undulations due to shrinkage and crepe. Differences between the two types of foils are also revealed.

A typical metal bushing material consists of a high-strength metal backing and a solid lubricant. These materials have higher load-carrying capacity and low friction during operation. Additionally, they are precision machined to tight tolerances. They also offer better thermal conductivity and better fatigue resistance. The accuracy of the metal bushing is improved due to the re-machining process that takes place after the bearing is assembled. Additionally, metal bushing materials are more resistant to wear than plastic bushing materials.

Plastic bushings are relatively inexpensive and readily available off the shelf. Also, the price of custom plastic bushings is relatively low. However, they are not recommended for heavy duty applications. Plastics degrade under high loads and can damage mating parts. Also, if the plastic bushings are not manufactured accurately, they can become misaligned. These are just some of the reasons for choosing metal bushings over plastic.

A mechanically bonded bushing 40 is placed over the stabilizer bar and compressed into the outer sleeve/bracket assembly. The outer metal member includes slotted holes that compensate for the tolerance stacking between the first and second bushing assemblies. Pre-assembly allows the assembly plant to receive a complete assembly ready for vehicle assembly, rather than sub-assembly at the vehicle manufacturing plant.

cost

Control arm bushings are a major component of modern vehicle suspension systems. Damaged bushings can negatively affect the handling and performance of your car. Replacing bushings on a car can cost $200 to $500. While that’s pretty cheap for a handful of control bushings, replacing the entire suspension system could set you back over $1,200. Thankfully, if you want to repair or replace the bushing yourself, you can do it yourself for a fraction of the cost.

If you decide to replace the control arm bushing yourself, it’s best to shop around for the best price. Many auto parts stores offer cheaper bushings that you don’t have to spend a fortune on. Even if you don’t drive for years, rubber can degrade and create cracks in the material. These cracks can be as deep as three-eighths of an inch. This makes it dangerous to drive a car with damaged control arm bushings.

Hiring a mechanic might be a good idea if you don’t like doing the work yourself. You can save money and time by repairing the control arm yourself, but you may have to hire a mechanic to do the job. Replacing the front sway bar bushing alone can cost between $450 and $900. While these components are relatively inexpensive, you can replace them for a better-handling car.

In some cases, sizing the bushings is a more economical option, but if you want to replace your entire suspension system, it’s better to buy a brand new lower limit. You can even save labor by buying a replacement part fork with a good lower portion. In addition to improving your car’s handling and ride, new bushings will add to your car’s overall value. If you are not sure which parts you need, ask your mechanic for a quote.

While the cost of replacing control arm bushings is relatively low, it’s a good idea to compare quotes from multiple mechanics. By getting multiple quotes for the same repair, you can save as much as $50 to $100 on the total cost of your car. In addition to labor costs, parts and labor can vary, so shop around to find the mechanic best suited for your car. There’s no reason to settle for sub-par service when you can save $50 or more!

editor by czh 2023-02-20

China NSK auto gear box ball bearing B45-106 bearing assembly

Kind: BALL

Structure: Deep Groove

Relevant Industries: Manufacturing Plant, Machinery Fix Retailers, Retail

Product Number: B45-106

Precision Rating: P0 P6 P5 P4 P2

Seals Sort: Open up ZZ 2RS

Number of Row: Single row

Materials: Chrome Steel

Item identify: CZPT Bearing B45-106

Cage: Metal Cage

Lubrication: Grease

Attribute: Extended Life

Software: Auto Gearbox

Service: OEM Tailored Companies

Vibration: Prolonged Lifestyle

Deal: Original Deal

Main Marketplace: Global

Packaging Particulars: Water-proof bag+Industrial rolls + neutral carton (bearing type, amount, bodyweight) +Expert packaging +export common pallet. (Can according to your demands).

Port: HangZhou or ZheJiang Port

| Product Title | Deep Groove Ball Bearing |

| Material | Chrome Steel GCr15 |

| Ball Bearings Attribute | 1 Long lifestyle span2 High rotating speed&Reduced sounds |

| Bearing Package | Pallet,wood situation,industrial packaging or as customers’ prerequisite. |

| Service | OEM Custom-made Provider Presented |

| Sample Plan | Sample Cost Free, Courier Cost Needed |

| Lead Time | 3 – 5 Times for In-inventory Items, Other folks require be Negotiated |

| Application | Household appliances, electrical power equipment, Japan Merged needle roller bearing NATA5904 20X37X23mm with angular contact ball bearing modest motor, medical products, workplace gear, sports activities tools, digital tools, and many others. |

What you should know about bushings

If you are in the market for a casing, there are a few things you should know before buying. First, a bushing is a mechanical part with a rotating or sliding shaft part. You can find them in almost all industrial applications due to their excellent load-carrying capacity and anti-friction properties. They are especially important in construction, mining, agriculture, hydropower, material handling, and more.

Casing application

The casing market is mainly driven by the growth of the power generation industry. The increasing electrification of Asia Pacific and the deployment of renewable energy in countries such as Saudi Arabia and the UAE are driving the demand for distribution transformer bushings. In addition, the demand for bushings in Western Europe is also likely to increase with the spread of renewable energy and the installation of electric vehicle charging infrastructure. However, the market in Asia Pacific is expected to remain small compared to the rest of the world.

Although bushings are relatively expensive, they are very durable and cost-effective. Furthermore, bushings have a variety of applications, making them an important component in power transformers. For example, power transformers often use bushings to achieve relative movement by sliding or rolling. The vehicle suspension system also uses rubber bushings for a smooth ride and rotating bushings for machine-related operations. They require precision machined parts and are especially useful in applications where high loads and friction must be controlled. Also, plastic bushings are used for wheels in dry kilns, where lubrication is often troublesome.

Transformers require constant monitoring, which is one of the reasons bushings are so important in power transformers. Any failure of these components could result in the total loss of the transformer and all surrounding equipment. To maintain high system reliability, utilities must monitor insulation in and around bushings, especially if transformers have been in use for decades. Some utilities have made monitoring the condition of their transformers an important part of their smart grid plans.

Material

The core of the dry casing has many material interfaces. The discharge most likely originates near the edges of the foils and can cause electrical tree growth or breakdown between adjacent foils. Several studies have investigated interfacial effects in composite insulating materials and concluded that the conditions under which the interface occurs is a key factor in determining the growth of electrical trees. This study found that material type and interface conditions are the two most important factors for the growth of electrical trees.

Bushings can be made of many different materials, depending on their purpose. The main purpose of the bushing is to support the assembly while protecting it. They must be stiff enough to support the load placed on them, and flexible enough to protect the shaft. Since the shaft is usually not centered on the bushing during rotation, the bushing must be durable enough to carry the load while still protecting the shaft. Here are several materials used for bushings:

A stabilizer bar assembly is a good example of pre-assembly. This pre-assembly enables the vehicle assembly plant to receive components ready for vehicle assembly. The prior art requires the vehicle assembly plant to separate the bushing from the stabilizer bar. However, the present invention eliminates this step and provides a mechanically rigid stabilizer bar assembly. It is designed to prevent audible squeals and improve vehicle performance and handling.

Hardened steel bushings are ideal for pivot and low speed applications. They are made of high carbon steel and fully hardened to 56-62 HRC. Bronze bushings require daily or weekly lubrication but are more expensive than plastic bushings. Plastic bushings are low cost, low maintenance, self lubricating and do not require regular lubrication. These are also suitable for applications with hard to reach parts.

application

Bushings have many applications in various industries. Most of the time, it is used for drilling. Its excellent chemical and mechanical properties can be used to protect various equipment. These components are versatile and available in a variety of materials. All sleeves are packaged according to national and international standards. They are used in many industrial processes from construction to drilling. Some application examples are listed below.The component 10 may contain a tank for a liquid such as fuel, and the object 12 may be made of fiber reinforced composite material. Sleeve assembly 16 is configured to ground component 10 and object 12 . It may be a bulkhead isolator 40 used to isolate electrical charges in aircraft hydraulic lines. Bushing assembly 16 is one of many possible uses for the bushing assembly. The following examples illustrate various applications of bushing assemblies.

Bearings are devices used to reduce friction between moving surfaces. They are a good choice for many applications as they are maintenance free and extend the life of machine components. They can be used in a variety of applications and are often used with plastic and metal materials. For example, Daikin offers bronze and brass bushings. Bushings have many other uses, but they are most commonly used in machines, especially when used in low-load environments.

The most common application for bushings is drilling. Swivel bushings can be used in almost any drilling application. For more complex applications, CZPT’s engineering department can create special designs to your specifications. The applications of bushings in machining centers are endless. By providing a smooth, reliable interface, bushings are an excellent choice for precision machining. They can also provide current paths.

Cost

When you have a vehicle that needs a bushing replacement, you may be wondering about the cost of a bushing replacement. The fact is, the cost of a bushing replacement will vary widely, depending on the specific car model. Some cars cost as little as $5, while other vehicles can cost up to $300. The replacement of a control arm bushing may not cost that much, but it’s important to know that it’s a relatively expensive part to replace.

Most mechanics charge around $375 for a job that involves replacing the bushing in a control arm. However, this price range can vary significantly, depending on whether the mechanic uses OE or aftermarket parts. In any case, the cost of labor is typically included in the price. Some mechanics may even include a labor charge, which is an additional cost. In general, however, the cost of a control arm bushing replacement is comparable to the cost of replacing a single bushing.

Control arm bushings are made of two metal cylinders secured together by a thick layer of rubber. Over time, these parts can deteriorate due to accidents, potholes, and off-roading. For this reason, it is important to replace them as soon as possible. Bushing replacement can save you money in the long run, and it’s important to have your vehicle repaired as soon as possible. If your control arm bushing is showing signs of wear, you should have it replaced before it becomes completely useless.

If you have decided to replace your suspension bushing yourself, the cost will be considerably lower than you would spend on the replacement of other components. If you have a mechanically-inclined mechanic, you can do it yourself. The parts and labour are reasonably cheap, but the most expensive part is the labor. Because it requires disassembling the wheel and suspension and installing a new bushing, it is important to have a mechanic who has a good understanding of vehicle mechanicry. The cost for control arm bushing replacement is between $20 and $80 per bushing, and a set of four costs approximately $300.

Disambiguation

If you’ve come across a page containing information about Bushing, you may have been looking for more information. This disambiguation page lists publications about the person, but these have not been assigned to him. We encourage you to contact us if you know who the true author of these publications is. Nevertheless, if you’re searching for specific information about Bushing, we recommend you start with CZPT.

editor by czh 2023-02-19

China Auto Bearing Toyota Bearing or Roller (FOR COUNTER GEAR REAR) OEM 90365-31006 supplier

Item Description

Solution Description:

| Merchandise: | TOYOTA BEARING OR ROLLER (FOR COUNTER Gear REAR) |

| Part No.: | 90365-31006 |

| Content: | STAINLESS Metal |

| Fit to: | TOYOTA 4Runner,Pickup,Previa,Van |

| Packing: | 1.Neutral Plastic Bag and Neutral Outer Carton, Pallet. 2.Custom-made package deal to cater for your brand promotion. three. Our JY Model packages( As under photograph displays) |

| Payment Terms: | thirty%TT deposit, the balance need to be paid out ahead of cargo. |

| Delivery Day: | one. Stocks. 3-7 times. 2. fifteen-twenty five days for LCL cargo. 3. 25-forty five days for FCL shipment. |

| Sample: | Charged, right after spot the get, we will return the sample payment. |

| Enterprise Line: | Various types and diverse auto designs supplied. |

Our Unique Support and Advantage:

| Tests: | Manufacturing facility QA test, before cargo, we will consider each merchandise video clip or pictures for closing comfirmation. |

| Grievance: | Undoubtedly exist. We received prolonged-time period organization with clients several many years thanks to our accountable to consumers needs and responce. If have, inside of 24 hours for solutions. VIP support on-line make contact with. If criticism, for our party, we will compensate your reduction and make alternative a.s.a.p. |

| Service: | Modest buy or sample order are suitable. One particular to One particular on-line business make contact with. |

| Trading Knowledge: | A lot of years export encounter, ready to assist build your new markets. |

| Sertificate: | ISO Syestem and TS16949 |

| Sea Port Available: | HangZhou Port or any china sea port are settle for. |

JIAYI Provide automobile areas for under:

Japanese vehicle: Honda,Toyota,Nissan,Mazda,Subaru,Mitsubishi,Suzuki,Isuzu

European automobile: Renault,Peugeot,Citroen,Fiat,Opel,BMW,Benz,VW,Audi,Skoda,Land Rover

American auto: Ford,Chrysler

Korean automobile: Hyundai,Kia,Daewoo

We are leading provider for below automobile areas:

Motor mounting/Transmission mount

Strut Mount/Silent block

Manage arm/wishbone/suspension arm

Brake method parts

Body areas.

Stabizer link /tie rod conclude/rack finish/ball joint

Air hose/cv boot

Bushing ect…

|

US $6 / Piece | |

500 Pieces (Min. Order) |

###

| Type: | Bearing |

|---|---|

| Material: | Stainless Steel |

| Tolerance: | P0 |

| Certification: | ISO9001, SGS |

| Clearance: | C0 |

| Car Make: | Toyota |

###

| Product: | TOYOTA BEARING OR ROLLER (FOR COUNTER GEAR REAR) |

| Part No.: | 90365-31006 |

| Material: | STAINLESS STEEL |

| Fit to: | TOYOTA 4Runner,Pickup,Previa,Van |

| Packing: | 1.Neutral Plastic Bag and Neutral Outer Carton, Pallet. 2.Customized package to cater for your brand promotion. 3. Our JY BRAND packages( As below picture shows) |

| Payment Terms: | 30%TT deposit, the balance should be paid before shipment. |

| Delivery Date: | 1. Stocks. 3-7 days. 2. 15-25 days for LCL shipment. 3. 25-45 days for FCL shipment. |

| Sample: | Charged, after place the order, we will return the sample fee. |

| Business Line: | Various types and different car models supplied. |

###

| Testing: | Factory QA test, before shipment, we will take each product video or pictures for final comfirmation. |

| Complaint: | Definitely exist. We got long-term business with customers many years due to our responsible to customers requirements and responce. If have, within 24 hours for solutions. VIP service online contact. If complaint, for our party, we will compensate your loss and make replacement a.s.a.p. |

| Service: | Small order or sample order are acceptable. One to One online business contact. |

| Trading Experience: | Many years export experience, willing to help develop your new markets. |

| Sertificate: | ISO Syestem and TS16949 |

| Sea Port Available: | Xiamen Port or any china sea port are accept. |

|

US $6 / Piece | |

500 Pieces (Min. Order) |

###

| Type: | Bearing |

|---|---|

| Material: | Stainless Steel |

| Tolerance: | P0 |

| Certification: | ISO9001, SGS |

| Clearance: | C0 |

| Car Make: | Toyota |

###

| Product: | TOYOTA BEARING OR ROLLER (FOR COUNTER GEAR REAR) |

| Part No.: | 90365-31006 |

| Material: | STAINLESS STEEL |

| Fit to: | TOYOTA 4Runner,Pickup,Previa,Van |

| Packing: | 1.Neutral Plastic Bag and Neutral Outer Carton, Pallet. 2.Customized package to cater for your brand promotion. 3. Our JY BRAND packages( As below picture shows) |

| Payment Terms: | 30%TT deposit, the balance should be paid before shipment. |

| Delivery Date: | 1. Stocks. 3-7 days. 2. 15-25 days for LCL shipment. 3. 25-45 days for FCL shipment. |

| Sample: | Charged, after place the order, we will return the sample fee. |

| Business Line: | Various types and different car models supplied. |

###

| Testing: | Factory QA test, before shipment, we will take each product video or pictures for final comfirmation. |

| Complaint: | Definitely exist. We got long-term business with customers many years due to our responsible to customers requirements and responce. If have, within 24 hours for solutions. VIP service online contact. If complaint, for our party, we will compensate your loss and make replacement a.s.a.p. |

| Service: | Small order or sample order are acceptable. One to One online business contact. |