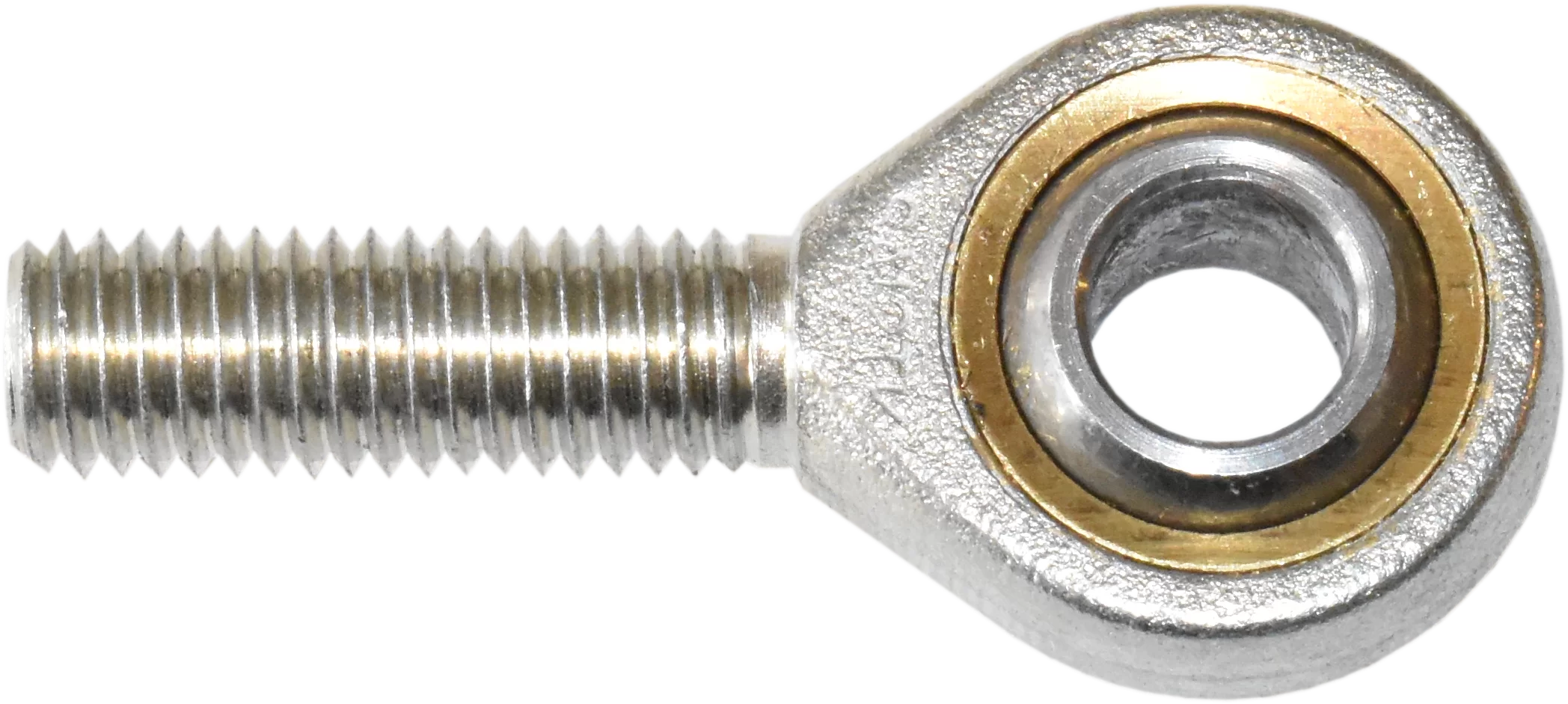

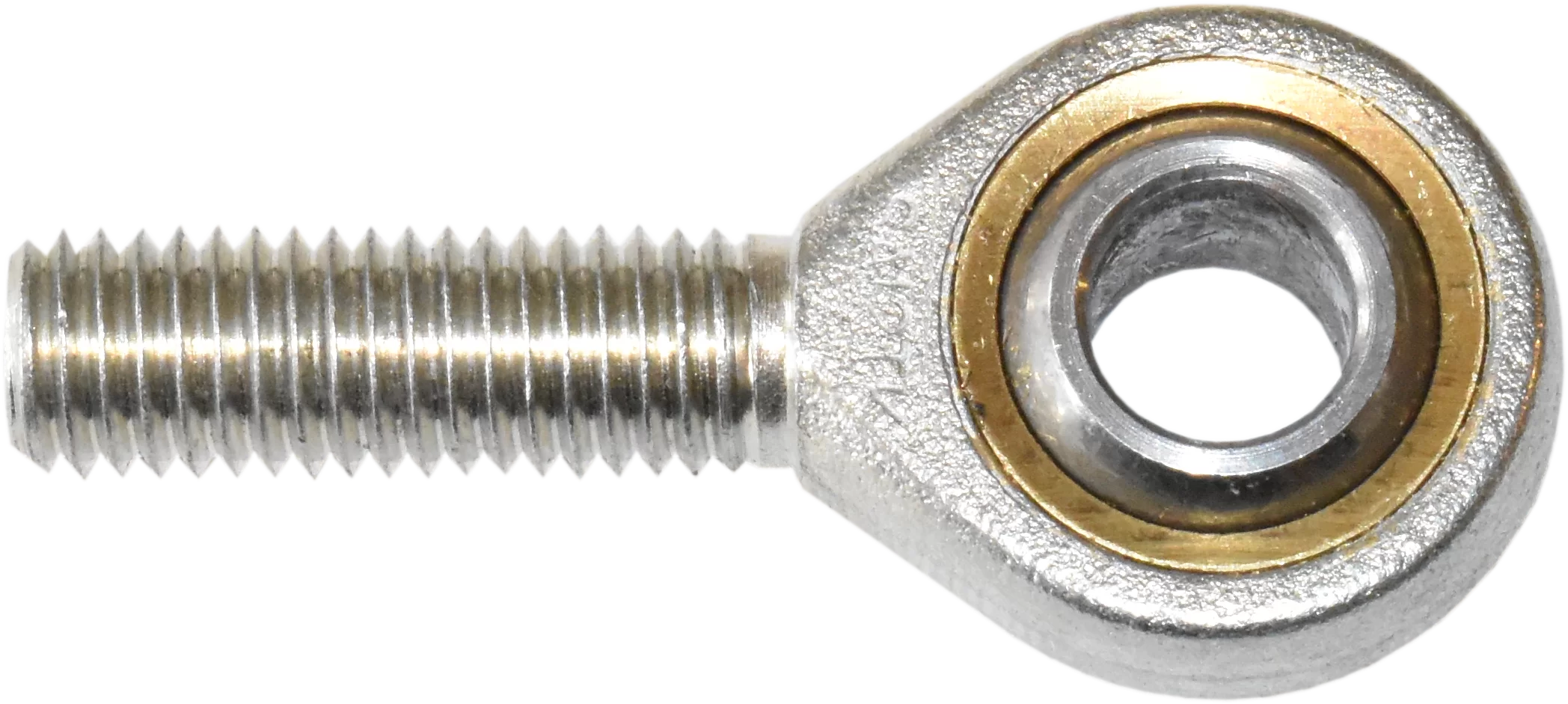

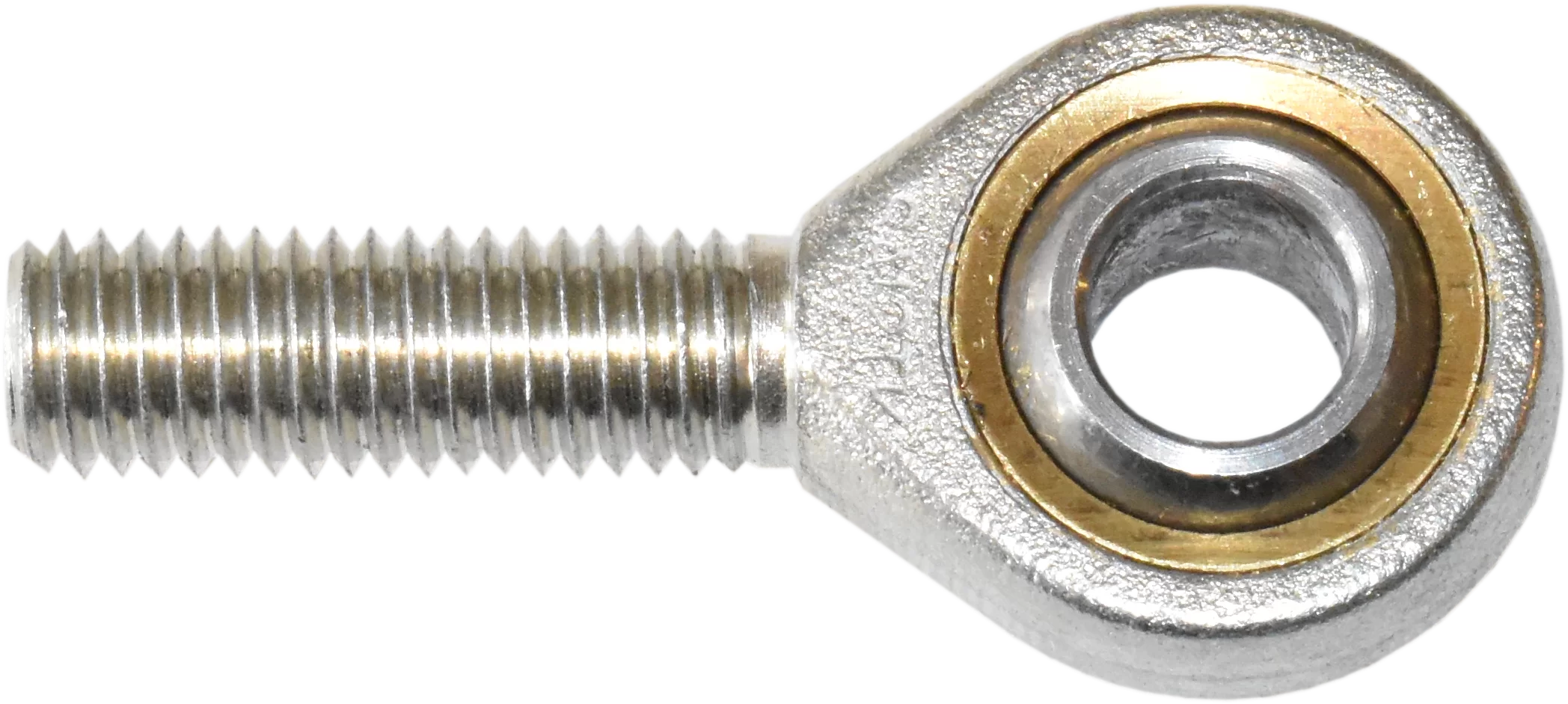

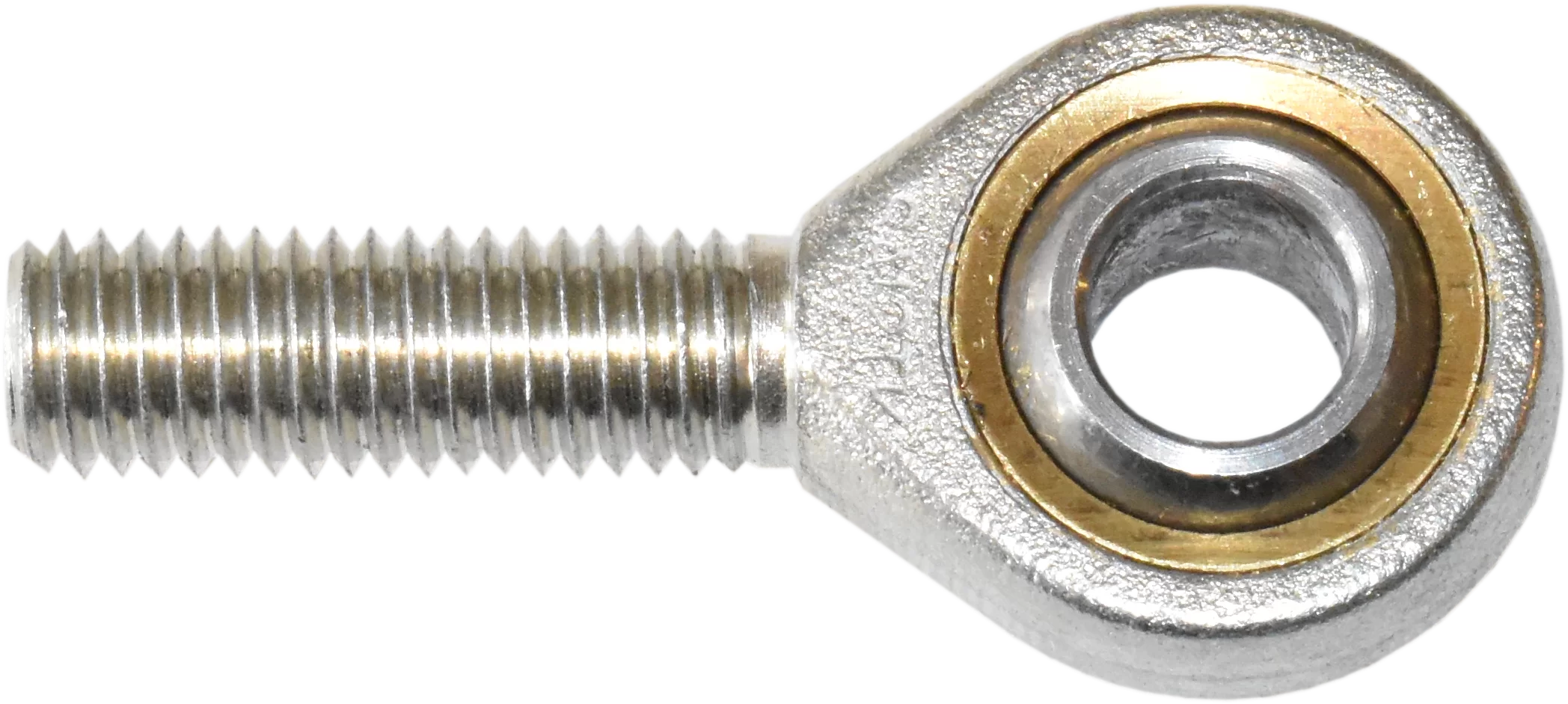

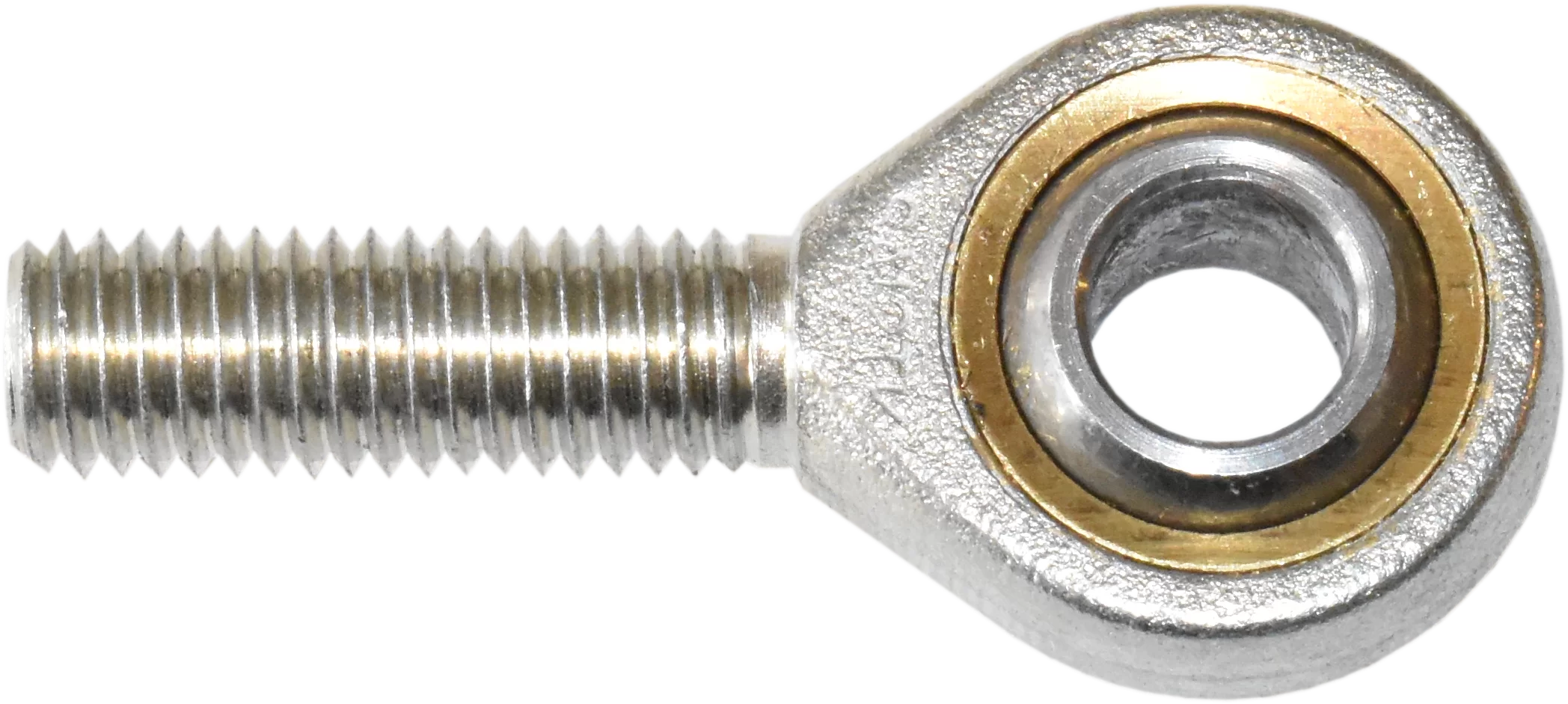

Product Description

Ball Joint rod end is as spare parts which widely required by many models of auto cars. We supply this series Rod End to customers according to clients’ drawings or samples. Customized and OEM orders are warmly welcomed!

Model No.: PCYML6T, PCYML8T, PCYML10T, PCYML12T

BALL

- 52100 Bearing Steel

- Heat Treated

- Hard Chrome Plated

- Precision Ground

BODY

- Chromoly Steel

- Heat Treated

- Black Oxide Coated

- PTFE Lined (PCM-T)

| Part Number | Boundary Dimensions (inch) |

Thread UNF-3A | Misalign Angle a° |

Ult. Radial Static Load ( lbs.) |

Approx. Bearing Weight (lbs) |

||||||

| Left Hand | Right Hand | B +0.0015 -0.0005 |

W ±0.005 |

A ±0.015 |

D Ref. | Ball Dia. Ref. | C +0.062 -0.031 |

||||

| PCYML6T | PCYMR6T | 0.375 | 0.875 | 2.125 | 1.125 | 0.812 | 1.375 | 3/8-24 | 55 | 11050 | 0.14 |

| PCYML7T | PCYMR7T | 0.4375 | 1 | 2.438 | 1.312 | 0.937 | 1.5 | 7/16-20 | 58 | 14449 | 0.22 |

| PCYML8-10T | PCYMR8-10T | 0.5 | 1.25 | 2.875 | 1.75 | 1.125 | 1.75 | 5/8-18 | 65 | 24158 | 0.44 |

| PCYML8T | PCYMR8T | 0.5 | 1.25 | 2.625 | 1.5 | 1.125 | 1.625 | 1/2-20 | 65 | 16240 | 0.33 |

| PCYML10-12T | PCYMR10-12T | 0.625 | 1.375 | 3.375 | 2 | 1.312 | 2 | 3/4-16 | 64 | 35710 | 0.68 |

| PCYML10T | PCYMR10T | 0.625 | 1.375 | 2.875 | 1.75 | 1.312 | 1.75 | 5/8-18 | 64 | 21219 | 0.51 |

| PCYML12T | PCYMR12T | 0.75 | 1.5 | 3.375 | 2 | 1.5 | 2 | 3/4-16 | 61 | 29127 | 0.79 |

Q1: Can I get a free sample?

A1: We provide samples free in freight collected. For special samples requirement, please contact us for more details.

Q2: How could I pay?

A2: We prefer T/T or L/C at sight. If you prefer other payment terms, please contact us freely.

Q3: What is your brand and packing way? Can you produce my brand and packing?

A3: Our brand is SGC and our own packing materials. We can make your brand. For more details, please contact us.

Q4: What is the delivery lead time?

A4: It depends on the order quantities. The mass production lead time is about 45-60 days after receipt of the deposit.

Q5: Are you manufacturer or trading company?

A5: We are manufacturer and exporter. We provide all kinds of OEM services for clients around the world.

Q6: Where is your main market?

A6: We export to the North America, Mexico, Australia, South-east Asia, Europe, U.A.E., Turkey, and other countries.

Our Services

1. Professional QC and QA team to make sure all products qualified before shipping.

2. Competitive price.

3 .Standard package to ensure the safe transportation.

4. Professional service.

Why choose us?

1. Production

Qualified production, competitive price, professional service.

2. Quality

All products are inspected 100% before shipment by relative testing equipments.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Rolling Element: | Single Row |

|---|---|

| Structure: | Rod End |

| Material: | Stainless Steel |

| Load Direction: | Radial Spherical Plain Bearing |

| Add Lubricant: | Self-lubricating |

| Outer Structure: | Outer Ring of Single-Slit |

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Selecting Size and Thread Type for Rod End Bearings

When choosing the appropriate size and thread type for a rod end bearing, several considerations are important:

1. Load Requirements: Determine the expected loads the rod end bearing will need to support. Choose a size and material that can handle these loads without deformation or premature wear.

2. Thread Direction: Consider whether you need left-hand or right-hand threads. This depends on the specific application and the direction in which the rod end bearing will be subject to forces or adjustments.

3. Thread Size and Pitch: Select the thread size and pitch that match the mating components or the mounting point. Ensure compatibility to avoid threading issues during installation.

4. Environmental Conditions: Consider the operating environment. If the rod end bearing will be exposed to moisture, chemicals, or extreme temperatures, choose a material and thread type that can withstand these conditions without corrosion or degradation.

5. Lubrication: Evaluate the lubrication method. Some rod end bearings have built-in lubrication features, while others require external lubrication. Ensure that the selected bearing and thread type align with your lubrication approach.

6. Misalignment Requirements: If the application involves misalignment, select a rod end bearing with appropriate articulation capabilities, which may require specific size and thread choices to allow for the necessary movement.

7. Compatibility: Ensure that the rod end bearing’s size and thread type are compatible with the connecting components, such as linkages, control arms, or push/pull rods.

8. Adjustability: In applications where adjustability is required, consider rod end bearings with male and female threads to allow for fine-tuning and alignment.

9. Regulations and Standards: Check if there are industry or safety regulations that dictate specific size or thread requirements for your application.

10. Maintenance: Consider ease of maintenance. Some rod end bearings have features that facilitate inspection and lubrication, which can be essential for extending their lifespan.

11. Cost and Availability: Finally, factor in the cost and availability of the chosen rod end bearing size and thread type. Ensure it fits within your budget and can be readily sourced when needed.

By carefully evaluating these considerations, you can select the most suitable rod end bearing size and thread type for your specific application, ensuring optimal performance and longevity.

Contribution of Rod End Bearings to Smooth Movement in Automotive Control Systems

Rod end bearings play a crucial role in ensuring the smooth movement of control systems in various automotive applications. Here’s how they contribute:

1. Steering Systems:

Rod end bearings are used in steering linkages and tie rod ends. They provide the necessary articulation and pivoting to allow the front wheels to turn smoothly, enabling precise steering control. The low friction and high load-bearing capacity of rod end bearings contribute to responsive and accurate steering in both manual and power steering systems.

2. Suspension Systems:

In suspension systems, rod end bearings are used in components like control arms and stabilizer links. They allow for controlled movement of the suspension, ensuring that the vehicle’s wheels maintain optimal contact with the road surface. This contributes to a smoother and more comfortable ride, improved handling, and better traction, especially when driving over uneven or bumpy terrain.

3. Throttle and Accelerator Linkages:

Rod end bearings are employed in throttle and accelerator linkages, where they assist in transmitting pedal inputs to the engine’s throttle body. The smooth articulation provided by rod end bearings ensures that drivers can easily modulate engine power, contributing to smooth acceleration and deceleration.

4. Gear Shift Linkages:

In manual transmissions, rod end bearings are used in gear shift linkages. They enable precise and smooth gear changes by allowing for the controlled movement of the shift lever. This ensures that gears engage smoothly, reducing drivetrain shock and vibration.

5. Convertible Roof Mechanisms:

In convertible cars, rod end bearings are used in the mechanisms that operate the folding and unfolding of the convertible roof. The smooth articulation of rod end bearings contributes to the seamless transition between open and closed roof positions, enhancing the overall driving experience.

Overall, rod end bearings are integral components in automotive control systems, ensuring the smooth and precise operation of various critical functions, including steering, suspension, throttle control, gear shifting, and convertible roof movement.

Rod End Bearings and Their Applications

Rod end bearings, also known as heim joints or rose joints, are mechanical components that consist of a spherical plain bearing with an inner ring and an outer ring. They are widely used in various mechanical applications due to their versatility and ability to provide articulation and movement in different directions. Here are some common applications of rod end bearings:

- Linkages: Rod end bearings are often used in linkages and control systems to transmit motion or force. They provide a connection point between two components, allowing for angular misalignment and smooth movement.

- Automotive Suspension: In automotive applications, rod end bearings are used in suspension systems to connect control arms, sway bars, and other components. They accommodate both rotational and pivoting movement.

- Aerospace: Rod end bearings play a crucial role in aircraft control systems, such as ailerons, flaps, and rudders. They ensure precise and responsive control of the aircraft’s movable surfaces.

- Construction Equipment: Heavy machinery, like cranes and excavators, utilizes rod end bearings in their control systems. These bearings provide flexibility and robustness in handling heavy loads and dynamic forces.

- Industrial Machinery: Various industrial machines, including conveyor systems, manufacturing equipment, and robotic arms, use rod end bearings to enable movement and articulation in mechanical linkages.

- Marine Applications: On boats and ships, rod end bearings are employed in steering and control systems. They withstand the harsh marine environment and provide reliable performance.

- Motion Control Systems: In applications like 3D printers, CNC machines, and robotic arms, rod end bearings are used to create flexible and precise motion control mechanisms.

- Hydraulic Cylinders: Rod end bearings are used in hydraulic cylinders to connect the piston rod to the external components. They allow for both linear motion and misalignment.

- Off-Road Vehicles: In off-road vehicles such as ATVs and dirt bikes, rod end bearings are used in suspension systems to absorb shocks and provide articulation over rough terrain.

Rod end bearings are valued for their ability to handle both static and dynamic loads, accommodate misalignment, and offer long-lasting performance in a wide range of applications.

editor by CX 2024-05-14

China Professional Spherical Joint Bearing Rod End Joint Bearing with Male Threaded SA22t/K SA22tk Fish Eye Bearing Spherical Plain Bearing for Gear Box ball bearing

Product Description

SA…TK Series Rod Ends is belong to maintenance-free Rod Ends bearing. The rod end body is equipped with a left-hand or right-hand external thread. The rod end body is formed by extrusion and the surface of the rod end body is galvanized. And The outer sphere is lined with PTFE synthetic material.

PRODUCTS CATALOGUE

| Part No: | Dimension | Load Rating(KN) | Weight | |||||||||||

| d | B | dk | C1 | d2 | G | h | L1 | L2 | R1S | a | Cr | Cor | g | |

| SA5T/K | 5 | 8 | 11.11 | 6 | 18 | M5X0.8 | 33 | 19 | 42 | 0.3 | 13 | 5.7 | 6 | 13 |

| SA6T/K | 6 | 9 | 12.7 | 6.75 | 20 | M6X1.0 | 36 | 21 | 46 | 0.3 | 13 | 7.2 | 7.65 | 20 |

| SA8T/K | 8 | 12 | 15.875 | 9 | 24 | M8X1.25 | 42 | 25 | 54 | 0.3 | 14 | 11.6 | 12.9 | 38 |

| SA10T/K | 10 | 14 | 19.05 | 10.5 | 28 | M10X1.5 | 48 | 28 | 62 | 0.3 | 13 | 14.5 | 18 | 55 |

| SA12T/K | 12 | 16 | 22.225 | 12 | 32 | M12X1.75 | 54 | 32 | 70 | 0.3 | 13 | 17 | 24 | 85 |

| SA14T/K | 14 | 19 | 25.4 | 13.5 | 38 | M14X2.0 | 60 | 36 | 78 | 0.3 | 16 | 24 | 31 | 140 |

| SA16T/K | 16 | 21 | 8.575 | 15 | 42 | M16X2.0 | 66 | 37 | 87 | 0.3 | 15 | 28.5 | 39 | 210 |

| SA18T/K | 18 | 23 | 31.75 | 16.5 | 46 | M18X1.5 | 72 | 41 | 94 | 0.3 | 15 | 42.5 | 47.5 | 290 |

| SA20T/K | 20 | 25 | 34.925 | 18 | 50 | M20X1.5 | 78 | 45 | 103 | 0.3 | 14 | 42.5 | 57 | 380 |

| SA22T/K | 22 | 28 | 38.1 | 20 | 54 | M22X1.5 | 84 | 48 | 111 | 0.3 | 15 | 57 | 68 | 480 |

| SA25T/K | 25 | 31 | 42.85 | 22 | 60 | M24X2 | 94 | 55 | 124 | 0.3 | 15 | 68 | 85 | 640 |

| SA28T/K | 28 | 35 | 47.6 | 24 | 66 | M27X2 | 103 | 62 | 136 | 0.3 | 15 | 86 | 107 | 800 |

| SA30T/K | 30 | 37 | 50.8 | 25 | 71 | M30X2 | 110 | 66 | 145 | 0.3 | 17 | 88 | 114 | 1100 |

| SA35TK | 35 | 43 | 57.1 | 28 | 81 | M36X3 | 140 | 85 | 180.5 | 0.3 | 16 | 1640 | ||

SA…PK Series

| Part No: | Dimension | Torque Kgf/cm | Load Rating(KN) | Weight | |||||||||||

| d | d1 | B | a | C1 | d2 | G | h1 | L4 | L3 | Cr | Cor | g | |||

| SA3PK | NOS-3 | 3 | 6.8 | 6 | 11 | 4.5 | 12 | M3x0.5 | 27 | 33 | 15 | 0.2~3.5 | 6 | ||

| SA4PK | NOS-4 | 4 | 7.6 | 7 | 12 | 5.3 | 14 | M4x0.7 | 30 | 37 | 17 | 0.2~3.5 | 10 | ||

| SA5PK | NOS-5 | 5 | 7.7 | 8 | 12 | 6 | 16 | M5x0.8 | 33 | 41 | 20 | 0.2~3.5 | 5.7 | 6 | 12 |

| SA6PK | NOS-6 | 6 | 9 | 9 | 10 | 6.8 | 18 | M6x1 | 36 | 45 | 22 | 0.2~3.5 | 7.2 | 7.65 | 19 |

| SA8PK | NOS-8 | 8 | 10.4 | 12 | 12 | 9 | 22 | M8x1.25 | 42 | 53 | 25 | 0.2~3.5 | 11.6 | 12.9 | 32 |

| SA10PK | NOS-10 | 10 | 12.9 | 14 | 12 | 10.5 | 26 | M10x1.5 | 48 | 61 | 29 | 0.2~3.5 | 14.5 | 18 | 54 |

| SA12PK | NOS-12 | 12 | 15.4 | 16 | 12 | 12 | 30 | M12x1.75 | 54 | 69 | 33 | 0.2~3.5 | 17 | 24 | 85 |

| SA14PK | NOS-14 | 14 | 16.9 | 19 | 14 | 13.5 | 34 | M14x2 | 60 | 77 | 36 | 0.2~3.5 | 24 | 31 | 126 |

| SA16PK | NOS-16 | 16 | 19.4 | 21 | 13 | 15 | 38 | M16x2 | 66 | 85 | 40 | 0.2~3.5 | 28.5 | 39 | 185 |

| SA18PK | NOS-18 | 18 | 21.9 | 23 | 14 | 17 | 42 | M18x1.5 | 72 | 93 | 44 | 0.2~3.5 | 42.5 | 47.5 | 258 |

| SA20PK | NOS-20 | 20 | 24.4 | 25 | 12 | 18 | 46 | M20x1.5 | 78 | 101 | 47 | 0.2~3.5 | 42.5 | 57 | 340 |

| SA22PK | NOS-22 | 22 | 25.8 | 28 | 13 | 20 | 50 | M22x1.5 | 84 | 109 | 51 | 0.2~3.5 | 57 | 68 | 435 |

| SA25PK | NOS-25 | 25 | 29.6 | 31 | 14 | 22 | 56 | M24x2 | 94 | 122 | 57 | 0.2~3.5 | 68 | 85 | 730 |

| SA28PK | NOS-28 | 28 | 32.3 | 35 | 16 | 26 | 66 | M27x2 | 110 | 143 | 66 | 0.2~3.5 | 1000 | ||

| SA30PK | NOS-30 | 30 | 34.8 | 37 | 16 | 26 | 66 | M30x2 | 110 | 143 | 66 | 0.2~3.5 | 1320 | ||

OUR WORKSHOP

OUR FACTORY

PACKAGING

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Rolling Element: | Single Row |

|---|---|

| Structure: | Rod End |

| Material: | Bearing Steel |

| Samples: |

US$ 8/Set

1 Set(Min.Order) | Order Sample |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Recent Advancements in Rod End Bearing Technology

Advancements in rod end bearing technology have led to improved performance and durability. Here are some insights into recent developments:

1. Enhanced Materials: Manufacturers are using advanced materials, including high-strength alloys and composites, to create rod end bearings that offer increased load-carrying capacity and improved corrosion resistance. These materials contribute to longer bearing life and better performance in challenging environments.

2. Sealing and Shielding: Innovations in sealing and shielding technologies have improved the protection of rod end bearings from contaminants, moisture, and harsh environmental conditions. These advancements extend maintenance intervals and increase bearing reliability.

3. Lubrication: Self-lubricating rod end bearings have become more prevalent, reducing the need for frequent manual lubrication. These bearings are designed to provide consistent and long-lasting lubrication, resulting in reduced maintenance requirements and longer service life.

4. 3D Modeling and Simulation: Manufacturers are increasingly using 3D modeling and simulation techniques to optimize rod end bearing designs. This allows for the creation of bearings that can handle higher loads and offer superior wear resistance while maintaining compact dimensions.

5. Customization: The ability to customize rod end bearings to specific application requirements has improved. This includes options for different thread types, materials, and sizes. Customization ensures that the bearing can meet the exact needs of the equipment it serves.

6. Environmental Sustainability: Some recent advancements focus on producing rod end bearings in an environmentally sustainable manner. Manufacturers are exploring eco-friendly materials and production processes to reduce the environmental impact of bearing manufacturing.

7. IoT Integration: In industrial applications, the integration of Internet of Things (IoT) technology allows for real-time monitoring and predictive maintenance of rod end bearings. Sensors and data analytics help detect early signs of wear or damage, optimizing maintenance schedules and minimizing downtime.

These recent advancements in rod end bearing technology have collectively improved the reliability, durability, and performance of these components in various mechanical systems. As technology continues to evolve, rod end bearings are expected to play an even more critical role in enhancing the efficiency and longevity of machinery and equipment.

Challenges and Solutions in Managing Load and Misalignment in Rod End Bearings

Rod end bearings often face challenges related to load capacity and misalignment in various applications. Here are the common challenges and solutions:

1. Radial and Axial Loads:

Challenge: Rod end bearings need to handle both radial and axial loads simultaneously in many applications.

Solution: Select rod end bearings with appropriate load ratings and materials to ensure they can withstand the expected loads. Also, proper maintenance and lubrication are essential for maximizing load-carrying capacity.

2. Misalignment:

Challenge: Misalignment can cause premature wear and reduced bearing lifespan.

Solution: Use self-aligning rod end bearings or incorporate spherical plain bearings to compensate for misalignment. Regular inspection and maintenance to correct any alignment issues are crucial.

3. Corrosion and Contaminants:

Challenge: Exposure to moisture, chemicals, and contaminants can lead to corrosion and damage.

Solution: Choose rod end bearings with suitable protective coatings or seals, such as PTFE liners or rubber boots, to prevent contaminants from entering. Stainless steel bearings offer enhanced corrosion resistance.

4. Lubrication:

Challenge: Inadequate lubrication can result in increased friction, overheating, and premature failure.

Solution: Follow the manufacturer’s lubrication recommendations and maintenance schedules. Proper lubrication ensures smooth operation and extends bearing life.

5. Shock and Impact Loads:

Challenge: Applications with frequent shock and impact loads can subject rod end bearings to excessive stress.

Solution: Choose rod end bearings with robust construction and materials to withstand shock loads. Regular inspections are necessary to detect early signs of damage.

By addressing these challenges with appropriate solutions, rod end bearings can perform optimally and provide long-lasting service in a wide range of applications.

Factors to Consider When Selecting a Rod End Bearing for a Specific Application

Choosing the right rod end bearing for a specific application is crucial to ensure optimal performance and longevity. Several factors should be taken into account during the selection process:

1. Load Capacity: Consider the magnitude and type of loads the bearing will need to support. Determine whether it will experience radial, axial, or a combination of loads. Select a rod end bearing with the appropriate load capacity rating to handle these loads.

2. Misalignment: Evaluate the degree of angular misalignment that may occur in the application. Some rod end bearings are designed to compensate for misalignment better than others. Choose a bearing that can accommodate the expected misalignment without compromising performance.

3. Environment: Take into account the operating environment. Consider factors like temperature, humidity, chemical exposure, and the presence of contaminants. Select a rod end bearing with suitable materials and protective features to withstand these conditions.

4. Lubrication: Proper lubrication is essential for the longevity and smooth operation of rod end bearings. Determine the lubrication method and frequency required for the application. Some rod end bearings come with built-in lubrication provisions or self-lubricating materials.

5. Thread Type and Size: The threaded shank of the rod end bearing should match the components it connects to. Consider the thread size and type (e.g., right-hand or left-hand threads) to ensure compatibility with your application.

6. Corrosion Resistance: If the application is in a corrosive environment, select a rod end bearing with corrosion-resistant materials or coatings. This is especially important in marine, chemical, or industrial settings.

7. Size and Weight Constraints: Ensure that the chosen rod end bearing fits within the space and weight limitations of the application. Measure the available space and consider weight restrictions when making your selection.

8. Operating Speed: Take into account the rotational or oscillatory speed of the bearing. Some rod end bearings are designed for high-speed applications, while others are better suited for low-speed or static applications.

9. Regulatory Compliance: In some industries, specific standards or regulations may apply to components like rod end bearings. Ensure that the selected bearing complies with any relevant industry standards or requirements.

10. Budget Constraints: While quality is essential, consider your budget constraints. Different rod end bearings come with varying price points. Choose a bearing that provides the necessary performance without exceeding your budget.

By carefully considering these factors, you can select the most suitable rod end bearing for your specific application, ensuring reliable and efficient operation.

editor by CX 2024-05-14

China factory China Wholesale Spherical Plain Bearing Radial Joint End Bearing Sliding Bearing ball bearing

Product Description

Why Choose Us

——————————————————————————————————————-

1.FREE SAMPLES:

Contact us by email or trade manager, we will send the free sampls according to your request.

2.World Class Bearing:

We provide our customers with all type of indigenous bearing with world class quality.

3. OEM or Non Stand Bearings:

Any requirement for Non standard bearings is Easily Fulfilled by us due to its vast knowledge and links in the industry.

4. Genuine products With Excellent Quality:

Company has always proved the 100% quality products it provides with genuine intent.

5.After Sales Service and technical Assistance:

Company provides after sales service and technical assistance as per the customers requirement and needs.

6. Quick Delivery:

The company provides just-in-time delivery with its streamlined supply chain.

7. Cost Saving:

We provide long-life, shock-resistant and high reliability bearings with excellent quality and better performance.

8.Attending customer queries promptly:

We believe that if customer are satisfied then it proves our worth well. Customers are always given quick support.

Products Description

——————————————————————————————————————-

UKL Rod End Bearing

Rod ends consist of an eye-shaped head with integral shank that forms a housing for a spherical plain bearing. They are used primarily on the ends of hydraulic or pneumatic pistons to join the cylinder to an associated component.

UKL supplies a wide assortment of standard rod ends with different thread and shank designs at the rod end housing, making them easy to install. The various sliding contact surface combinations of the bearings make the rod ends suitable for the operating conditions of many applications.

Features:

1. Bearings with a stretching rod, stretching with right or left-hand male thread.

2. To plate zinc on the surface of rod body, the housing with a lubricartion hole or a grease nipple.

3. Rod ends permissible operating temperature, are available on – 30 °C to + 80 °C temperature range of use, and keep the right to bear ability.

Application:

Rod end bearing are widely used in hydraulic engineering, metal forming machine tools, construction machinery, automation equipment, automotive shock absorbers, irrigation machinery and other industries.

Product Display

——————————————————————————————————————-

Male Therad Rod End Bearing

Female Thread Rod End Bearing

Factory&Equipment

——————————————————————————————————————-

Inspection&Packaging

——————————————————————————————————————-

Application Scenario

——————————————————————————————————————-

Certifications

——————————————————————————————————————-

FAQ

1.Q:What the MOQ of your company?

A:MOQ is 1pc.

2.Q:Could you accept OEM and customize?

A:YES,we can customize for you according to sample or drawing.

3.Q:Could you supply sample for free?

A:Yes,we can supply sample for free,do you mind to buy her a ticket?

4.Q:IS you company factory or Trade Company?

A:We have our own factory ;our type is factory +trade.

5.Q:Could you tell me the material of your bearing?

A:We have chrome steel,carbon steel and staninless steel,ceramic and plastic material.

6.Q:Could you offer door to door service?

A:Yes,by express(DHL,FEDEX,TNT,EMS,4-10 days to your city.)

7.Q:Coould you tell me the payment term of your company can accept?

A:T/T.L/C,Western Union,PayPal

8.Q:Could you tell me the delivery time of your doods?

A:If stock,in 7days or base on your order quantity. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Rolling Element: | Single Row |

|---|---|

| Structure: | Rod End |

| Material: | Bearing Steel |

| Load Direction: | Radial Spherical Plain Bearing |

| Add Lubricant: | Non Self-lubricating |

| Outer Structure: | Whole Outer Ring |

| Samples: |

US$ 0.01/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Contribution of Rod End Bearings to Complex Motion in Industrial Machinery

Rod end bearings play a significant role in ensuring the proper functioning of industrial machinery with complex motion. Here’s how they contribute:

1. Articulation and Pivoting:

Industrial machinery often requires components that can pivot and articulate in multiple directions. Rod end bearings provide a flexible connection point, allowing for a wide range of motion. They are commonly used in applications like robotic arms, conveyor systems, and material handling equipment, where precise movement and adaptability are essential.

2. Load Transmission:

Industrial machinery frequently deals with heavy loads and dynamic forces. Rod end bearings efficiently transmit these loads from moving components to stationary structures. Whether it’s the linear movement of a press or the tilting motion of a heavy-duty crane, rod end bearings enable the smooth transfer of forces, reducing wear and tear on the machinery.

3. Misalignment Compensation:

Machinery parts can become misaligned due to manufacturing tolerances, wear, or other factors. Rod end bearings excel at compensating for misalignments, ensuring that moving parts remain connected and operational. This capability is crucial in applications with variable alignment requirements, such as industrial automation systems and assembly line equipment.

4. Precision and Control:

Many industrial processes demand precision and control over motion. Rod end bearings help achieve this by providing a reliable connection point that can be adjusted and fine-tuned. This precision is essential in applications like CNC machinery, where the accuracy of tool movement directly impacts the quality of the final product.

5. Corrosion Resistance:

Industrial machinery operates in diverse environments, some of which may expose components to moisture and corrosive substances. Rod end bearings are available in various materials, including stainless steel, which offers excellent corrosion resistance. This ensures the bearings’ longevity and reliability, even in challenging conditions.

Overall, rod end bearings contribute to the efficient and reliable operation of industrial machinery with complex motion requirements. Their ability to accommodate articulation, handle heavy loads, compensate for misalignment, provide precision, and resist corrosion makes them invaluable components in various industrial applications.

Challenges and Solutions in Managing Load and Misalignment in Rod End Bearings

Rod end bearings often face challenges related to load capacity and misalignment in various applications. Here are the common challenges and solutions:

1. Radial and Axial Loads:

Challenge: Rod end bearings need to handle both radial and axial loads simultaneously in many applications.

Solution: Select rod end bearings with appropriate load ratings and materials to ensure they can withstand the expected loads. Also, proper maintenance and lubrication are essential for maximizing load-carrying capacity.

2. Misalignment:

Challenge: Misalignment can cause premature wear and reduced bearing lifespan.

Solution: Use self-aligning rod end bearings or incorporate spherical plain bearings to compensate for misalignment. Regular inspection and maintenance to correct any alignment issues are crucial.

3. Corrosion and Contaminants:

Challenge: Exposure to moisture, chemicals, and contaminants can lead to corrosion and damage.

Solution: Choose rod end bearings with suitable protective coatings or seals, such as PTFE liners or rubber boots, to prevent contaminants from entering. Stainless steel bearings offer enhanced corrosion resistance.

4. Lubrication:

Challenge: Inadequate lubrication can result in increased friction, overheating, and premature failure.

Solution: Follow the manufacturer’s lubrication recommendations and maintenance schedules. Proper lubrication ensures smooth operation and extends bearing life.

5. Shock and Impact Loads:

Challenge: Applications with frequent shock and impact loads can subject rod end bearings to excessive stress.

Solution: Choose rod end bearings with robust construction and materials to withstand shock loads. Regular inspections are necessary to detect early signs of damage.

By addressing these challenges with appropriate solutions, rod end bearings can perform optimally and provide long-lasting service in a wide range of applications.

Factors to Consider When Selecting a Rod End Bearing for a Specific Application

Choosing the right rod end bearing for a specific application is crucial to ensure optimal performance and longevity. Several factors should be taken into account during the selection process:

1. Load Capacity: Consider the magnitude and type of loads the bearing will need to support. Determine whether it will experience radial, axial, or a combination of loads. Select a rod end bearing with the appropriate load capacity rating to handle these loads.

2. Misalignment: Evaluate the degree of angular misalignment that may occur in the application. Some rod end bearings are designed to compensate for misalignment better than others. Choose a bearing that can accommodate the expected misalignment without compromising performance.

3. Environment: Take into account the operating environment. Consider factors like temperature, humidity, chemical exposure, and the presence of contaminants. Select a rod end bearing with suitable materials and protective features to withstand these conditions.

4. Lubrication: Proper lubrication is essential for the longevity and smooth operation of rod end bearings. Determine the lubrication method and frequency required for the application. Some rod end bearings come with built-in lubrication provisions or self-lubricating materials.

5. Thread Type and Size: The threaded shank of the rod end bearing should match the components it connects to. Consider the thread size and type (e.g., right-hand or left-hand threads) to ensure compatibility with your application.

6. Corrosion Resistance: If the application is in a corrosive environment, select a rod end bearing with corrosion-resistant materials or coatings. This is especially important in marine, chemical, or industrial settings.

7. Size and Weight Constraints: Ensure that the chosen rod end bearing fits within the space and weight limitations of the application. Measure the available space and consider weight restrictions when making your selection.

8. Operating Speed: Take into account the rotational or oscillatory speed of the bearing. Some rod end bearings are designed for high-speed applications, while others are better suited for low-speed or static applications.

9. Regulatory Compliance: In some industries, specific standards or regulations may apply to components like rod end bearings. Ensure that the selected bearing complies with any relevant industry standards or requirements.

10. Budget Constraints: While quality is essential, consider your budget constraints. Different rod end bearings come with varying price points. Choose a bearing that provides the necessary performance without exceeding your budget.

By carefully considering these factors, you can select the most suitable rod end bearing for your specific application, ensuring reliable and efficient operation.

editor by CX 2024-05-13

China high quality Custom Private Label Right or Left Hand Ball Joint Rod End Bearing with Best Sales

Product Description

| Custom Private Label Right or Left Hand Ball Joint Rod End Bearing |

HangZhou JOY INTERNATIONAL TRADE CO.LTD.is an industrial and trade enterprise integrating the development,design,production and sales of Vehicles Parts and Accessories,CNC Machining,Metal Stamping,Fasteners,Plastic and Rubber Parts etc.Providing customers with one-stop supply chain services is our main business.Keep customers satisfied is our enterprise purpose.Radiation Europe,the United States,Australia,UK and other countries and regions,with good customer resources and channels.

With quality control system of lSO/TS 16949:2009,the company has equipped with a full range of advanced testing equipment and also own several experienced engineers and quality controllers,which can ensure that the product quality is effectively controlled in the whole production process.Effective inspection report with corresponding material certificate will be provided for each shipment.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Yes |

|---|---|

| Warranty: | 12 Months |

| Car Model: | Control Arm |

| Component: | Ball Joint |

| Payment: | Tt/LC |

| Shipment: | by Sea/ Air /Express |

| Samples: |

US$ 76/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Recent Advancements in Rod End Bearing Technology

Advancements in rod end bearing technology have led to improved performance and durability. Here are some insights into recent developments:

1. Enhanced Materials: Manufacturers are using advanced materials, including high-strength alloys and composites, to create rod end bearings that offer increased load-carrying capacity and improved corrosion resistance. These materials contribute to longer bearing life and better performance in challenging environments.

2. Sealing and Shielding: Innovations in sealing and shielding technologies have improved the protection of rod end bearings from contaminants, moisture, and harsh environmental conditions. These advancements extend maintenance intervals and increase bearing reliability.

3. Lubrication: Self-lubricating rod end bearings have become more prevalent, reducing the need for frequent manual lubrication. These bearings are designed to provide consistent and long-lasting lubrication, resulting in reduced maintenance requirements and longer service life.

4. 3D Modeling and Simulation: Manufacturers are increasingly using 3D modeling and simulation techniques to optimize rod end bearing designs. This allows for the creation of bearings that can handle higher loads and offer superior wear resistance while maintaining compact dimensions.

5. Customization: The ability to customize rod end bearings to specific application requirements has improved. This includes options for different thread types, materials, and sizes. Customization ensures that the bearing can meet the exact needs of the equipment it serves.

6. Environmental Sustainability: Some recent advancements focus on producing rod end bearings in an environmentally sustainable manner. Manufacturers are exploring eco-friendly materials and production processes to reduce the environmental impact of bearing manufacturing.

7. IoT Integration: In industrial applications, the integration of Internet of Things (IoT) technology allows for real-time monitoring and predictive maintenance of rod end bearings. Sensors and data analytics help detect early signs of wear or damage, optimizing maintenance schedules and minimizing downtime.

These recent advancements in rod end bearing technology have collectively improved the reliability, durability, and performance of these components in various mechanical systems. As technology continues to evolve, rod end bearings are expected to play an even more critical role in enhancing the efficiency and longevity of machinery and equipment.

Signs of Wear or Damage in Rod End Bearings and Replacement Guidelines

Rod end bearings are critical components in various mechanical systems, and it’s essential to monitor them for signs of wear or damage. Here are common indicators and guidelines for replacement:

1. Excessive Play or Looseness: If you notice excessive play or looseness in the rod end bearing, it’s a clear sign of wear. This can result in imprecise control and reduced system performance, so replacement is recommended.

2. Unusual Noises: Unusual noises such as knocking, clicking, or squeaking during movement are often indicative of rod end bearing issues. These noises can be a result of worn bearing surfaces or damaged components. Address the problem promptly to prevent further damage.

3. Corrosion or Rust: Exposure to moisture or harsh environmental conditions can lead to corrosion and rust on rod end bearings. Corroded bearings may not move smoothly, impacting system operation. If you observe significant corrosion, consider replacement.

4. Visible Damage: Any visible damage, such as cracks, dents, or deformation of the bearing’s body or components, should be taken seriously. Damaged rod end bearings can fail unexpectedly, leading to safety risks and system malfunctions. Replace them if damage is detected.

5. Reduced Range of Motion: If the rod end bearing restricts the range of motion or does not articulate smoothly, it may be worn or damaged. This can affect the performance of the associated system. Replacement is advisable to restore proper functionality.

6. Increased Friction: A sudden increase in friction during movement can indicate a lack of lubrication, contamination, or damage to the bearing surfaces. Re-greasing and cleaning may help, but if the issue persists, consider replacing the bearing.

7. Maintenance Intervals: Depending on the application, rod end bearings may have recommended maintenance intervals. Follow these guidelines and inspect the bearings during routine maintenance. If wear or damage is detected, replace them as necessary.

8. Safety Concerns: In safety-critical applications, it’s vital to prioritize bearing replacement at the first sign of wear or damage. Failure to do so can result in accidents or system failures with serious consequences.

Regular inspection and maintenance of rod end bearings are essential to ensure the continued reliability and performance of mechanical systems. When any of the above signs are observed, it’s advisable to replace the bearings promptly to prevent further issues and potential safety risks.

Impact of Proper Lubrication on Rod End Bearings

Proper lubrication is crucial for enhancing the performance and extending the longevity of rod end bearings. Here’s how it impacts these aspects:

1. Reduced Friction: Lubrication creates a film between moving parts, reducing friction. This minimizes wear and heat generation, leading to smoother and more efficient operation of the rod end bearing.

2. Wear Prevention: Lubrication helps prevent wear and surface damage on bearing components, particularly the ball and raceway. This is vital for the long-term durability of the bearing.

3. Corrosion Resistance: In applications exposed to moisture or corrosive substances, lubrication provides a protective barrier, preventing rust and corrosion on the bearing’s surfaces. This is especially important in outdoor or marine environments.

4. Noise Reduction: Adequate lubrication reduces noise and vibration in the bearing. This is important for applications where noise levels must be minimized, such as in the aerospace or medical industries.

5. Temperature Control: Lubrication helps dissipate heat generated by friction. Effective temperature control prevents overheating, which can lead to premature bearing failure.

6. Seal and Shield Function: Lubrication also works in conjunction with bearing seals and shields to keep contaminants out. It maintains a clean and contaminant-free internal environment, further increasing the bearing’s longevity.

7. Longevity: Proper lubrication significantly extends the service life of rod end bearings. Regular maintenance and relubrication schedules are essential for maximizing the bearing’s operational lifespan.

8. Efficiency: Lubrication contributes to the overall efficiency of the bearing, ensuring that it operates at peak performance levels, even under heavy loads or misalignment conditions.

9. Performance Consistency: Adequate lubrication helps maintain consistent performance over time. This is especially important in critical applications where performance fluctuations could lead to safety or quality concerns.

It’s important to use the lubricant recommended by the bearing manufacturer and follow their guidelines for lubrication intervals. Over-lubrication can be as detrimental as under-lubrication, so maintaining the right balance is essential.

Regular inspections and maintenance routines should be established to monitor the lubrication condition and reapply lubricant as needed. This proactive approach ensures that rod end bearings operate effectively, offering reliability and a longer service life.

editor by CX 2024-05-08

China manufacturer China Factory Ball Joint Bearing Rod End Bearings (NHS3 NHS4 NHS5 NHS6 NHS8 NHS10 NHS12 NHS14 NHS16 NHS18 NHS20 NHS22 NHS25 NHS28 NHS30) bearing example

Product Description

China Factory Ball Joint Bearing Rod End Bearings (NHS3 NHS4 NHS5 NHS6 NHS8 NHS10 NHS12 NHS14 NHS16 NHS18 NHS20 NHS22 NHS25 NHS28 NHS30)

Product Description

Rod end bearing, also known as a heim joint (N. America) or rose joint (U.K. and elsewhere), is a mechanical articulating joint.

It is a kind of sliding bearing with special structure. Its structure is simpler than that of rolling bearing. It is mainly composed of an inner ring with outer sphere and an outer ring with inner sphere. It can bear large load. According to its different types and structures, it can bear radial load, axial load or combined load with radial and axial at the same time. The plain bearing is generally used for low-speed swing motion (i.e. angular motion). Because the sliding surface is spherical, it can also make inclined motion (i.e. centering motion) within a certain angle range. It can still work normally when the non concentricity between the support shaft and the shaft shell hole is large.

| Material | Outer Shell: Carbon Steel; Inner Ball: Bearing Steel |

| Thread Type | Female thread/ Internal thread/ Hollow thread; Left-hand / right-hand thread. |

| Surface Treatment | Forging/ Machining; Zinc, brass, chrome, nickel plating. |

| Model No. |

PHS5,PHS6, PHS8, PHS10, PHS12, PHS14, PHS16, PHS18, PHS20, PHS22, PHS25, PHS28, PHS30. POS5, POS6, POS8, POS10, POS12, POS14, POS16, POS18, POS20, POS22, POS25, POS28, POS30. SI5T/K,SI6T/K, SI8T/K, SI10T/K, SI12T/K, SI14T/K, SI16T/K, SI18T/K, SI20T/K, SI22T/K, SI25T/K, SI28T/K, SI30T/K. SA5T/K,SA6T/K, SA8T/K, SA10T/K, SA12T/K, SA14T/K, SA16T/K, SA18T/K, SA20T/K, SA22T/K, SA25T/K, SA28T/K, SA30T/K. NHS3,NHS4,NHS5,NHS6,NHS8,NHS10,NHS12,NHS14,NHS16,NHS18,NHS20,NHS22,NHS25,NHS28,NHS30 NOS3,NOS4,NOS5,NOS6,NOS8,NOS10,NOS12,NOS14,NOS16,NOS18,NOS20,NOS22,NOS25,NOS28,NOS30 SI5E,SI6E,SI8E, SI10E, SI12E, SI15ES, SI17ES, SI20ES, SI25ES, SI30ES, SI35ES, SI40ES, SI45ES, SI50ES, SI60ES, SI70ES, SI80ES. SA5E,SA6E, SA8E, SA10E, SA12E, SA15ES, SA17ES, SA20ES, SA25ES, SA30ES, SA35ES, SA40ES, SA45ES, SA50ES, SA60ES, SA70ES, SA80ES. |

| Other Material | Outer Shell: Carbon Steel; Inner Ball: Carbon Steel |

| Payment | T/T, paypal, West Union, L/C |

| Application | Rod end bearing is widely used for engineering hydraulic oil cylinder, Forging machine tools, engineering machinery, automation equipment, car shock absorber, hydraulic machinery and other industries. Self lubricating joints and auxiliary promise used in water conservancy, professional machinery and other industries. |

| OEM/ODM | We are professional bearing manufacturer. OEM & Customized Service are both accepted to our R&D department. If you need please show us with your drawing while inquiry. Thank you |

Detailed Photos

Company Profile

HangZhou City CZPT Bearing Co., Ltd. is a professional manufacturer of linear motion products with many years’ experience. We are specialized in the producing linear shaft, linear guides, ball screws, linear bearings, linear CZPT blocks, ball screw end supports, linear rails, cam followers with good quality and competitive price. Our company is located in HangZhou city, ZHangZhoug province, close to HangZhou port and HangZhou city.

Our products are widely used in precise machines, fitness equipment, printing machines, packing machines, medical and food machines, textile machinery and other machines and supplementary equipment. Our products sell well in North America, West Europe, Australia, Southeast Asia, Middle East, South America and other regions.

After Sales Service

Our Quality:

Quality is the life . We use only the best quality material to ensure the standard of our product range is of the highest caliber.All products we sold out are strictly selected and tested by our QC department.

Warranty:

All products may have problem after used by a period of time. We provide 1 year warranty for all products.

Payment:

We accept payment via TT (Bank transfer), Paypal,Western Union, and Money Gram.

We accept bank transfer for large orders. For small order, you’d better pay via Paypal,Western union or Money Gram

Shipping:

We offer as many shipping options as possible, including DHL, UPS, TNT, FEDEX and EMS, Airfreight and by Sea.

FAQ

1. Are you factory or trading company?

We are professional manufacturer with most competitive price and high quality, 15 year’s experience.

2.What’s your product range?

We are specialized in producing linear shafts, linear bearings, linear guides, linear rails, ball screws,cam follower and other linear motion units.

3.Do you offer OEM&ODM services?

Yes, OEM, ODM is welcomed

4.How Can I get some samples?

We are honored to offer samples. You are requested to pay the shipping cost and some samples cost.

5.What does your factory do about quality control?

We uphold the tenet of “Quality is the future, we have passed ISO9001 certification, and we have strict procedures to control quality.

6. How can I get a quotation?

You can send quotation below or email to us. you can contact dirrectly with us through TM or WhatsApp,Skype as you like.Call any time if you are urgent.

If you have any question, please send message at below to me /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Rolling Element: | Single Row |

|---|---|

| Structure: | Rod End |

| Material: | Bearing Steel |

| Load Direction: | Thrust Spherical Plain Bearing |

| Add Lubricant: | Self-lubricating |

| Outer Structure: | Whole Outer Ring |

| Customization: |

Available

| Customized Request |

|---|

Impact of Temperature Variations and Environmental Conditions on Rod End Bearing Performance

Rod end bearings can be affected by temperature variations and environmental conditions, which may impact their performance. Here’s how these factors come into play:

1. Temperature Variations:

Temperature changes can influence the lubrication and material properties of rod end bearings. Extreme cold can cause lubricants to thicken, potentially leading to increased friction and reduced efficiency. On the other hand, high temperatures can cause lubricants to thin, which may result in inadequate lubrication and accelerated wear. Proper lubrication and material selection are crucial to ensure that rod end bearings operate optimally across a range of temperatures.

2. Contaminants and Moisture:

Industrial environments often expose rod end bearings to contaminants such as dust, dirt, and chemicals. Additionally, moisture and humidity can lead to corrosion and reduced bearing lifespan. Seals and boots can help protect rod end bearings from these elements, maintaining their performance and preventing premature failure. Regular maintenance, including cleaning and re-lubrication, is essential to counteract the effects of contaminants and moisture.

3. Corrosion Resistance:

Rod end bearings are available in various materials, including stainless steel, which offers excellent corrosion resistance. This is especially important in environments where exposure to moisture or chemical agents is common. Choosing the right material for the specific environmental conditions is crucial to prevent corrosion-related issues and ensure the long-term functionality of the bearings.

4. Material Expansion and Contraction:

Temperature variations can lead to the expansion and contraction of materials. This can affect the clearances within the bearing, potentially causing issues such as increased play or reduced load-carrying capacity. Proper bearing design and material selection, as well as regular inspections, can mitigate these effects.

5. Lubrication Intervals:

In extreme temperature or environmental conditions, more frequent lubrication may be necessary to maintain optimal performance and protect rod end bearings from premature wear. Lubricants should be chosen based on their suitability for the given operating conditions.

Overall, temperature variations and environmental conditions can impact rod end bearing performance. Proper maintenance, material selection, and environmental safeguards, such as seals and boots, are essential to ensure that rod end bearings continue to function reliably in diverse operating environments.

Challenges and Solutions in Managing Load and Misalignment in Rod End Bearings

Rod end bearings often face challenges related to load capacity and misalignment in various applications. Here are the common challenges and solutions:

1. Radial and Axial Loads:

Challenge: Rod end bearings need to handle both radial and axial loads simultaneously in many applications.

Solution: Select rod end bearings with appropriate load ratings and materials to ensure they can withstand the expected loads. Also, proper maintenance and lubrication are essential for maximizing load-carrying capacity.

2. Misalignment:

Challenge: Misalignment can cause premature wear and reduced bearing lifespan.

Solution: Use self-aligning rod end bearings or incorporate spherical plain bearings to compensate for misalignment. Regular inspection and maintenance to correct any alignment issues are crucial.

3. Corrosion and Contaminants:

Challenge: Exposure to moisture, chemicals, and contaminants can lead to corrosion and damage.

Solution: Choose rod end bearings with suitable protective coatings or seals, such as PTFE liners or rubber boots, to prevent contaminants from entering. Stainless steel bearings offer enhanced corrosion resistance.

4. Lubrication:

Challenge: Inadequate lubrication can result in increased friction, overheating, and premature failure.

Solution: Follow the manufacturer’s lubrication recommendations and maintenance schedules. Proper lubrication ensures smooth operation and extends bearing life.

5. Shock and Impact Loads:

Challenge: Applications with frequent shock and impact loads can subject rod end bearings to excessive stress.

Solution: Choose rod end bearings with robust construction and materials to withstand shock loads. Regular inspections are necessary to detect early signs of damage.

By addressing these challenges with appropriate solutions, rod end bearings can perform optimally and provide long-lasting service in a wide range of applications.

Design Principles and Functions of Rod End Bearings

Rod end bearings, also known as heim joints or rose joints, are essential components in various mechanical applications, where articulation and precise control of movement are required. These bearings are designed with specific principles and functions in mind:

Design Principles:

Rod end bearings consist of a spherical plain bearing, also known as a spherical plain bushing, within a housing. The design principles are as follows:

- Spherical Plain Bearing: The heart of a rod end bearing is a spherical plain bearing. This bearing allows the inner ring to tilt and rotate in multiple directions. It consists of an inner and outer ring with a sliding layer of material in between, often made from self-lubricating materials.

- Housing: The spherical plain bearing is housed within a protective casing, typically made of metal or other durable materials. The housing provides structural support and retains the bearing components.

- Threaded Shank: The outer part of the housing is often shaped as a threaded shank, allowing for easy attachment to various mechanical components, such as linkages or control arms.

- Lubrication Fittings: Many rod end bearings have provisions for lubrication fittings to ensure smooth articulation and reduce friction.

Functions:

Rod end bearings serve several crucial functions in mechanical systems:

- Articulation: Rod end bearings provide articulation, enabling components to pivot, swivel, and move in multiple directions. This function is vital in applications requiring flexibility and control over movement.

- Angular Misalignment Compensation: They can compensate for both static and dynamic angular misalignment. This is particularly useful in situations where components may not align perfectly due to varying factors like vibration or assembly tolerances.

- Load Transmission: Rod end bearings can transmit static and dynamic loads, making them suitable for applications involving force or load transfer. They are used in machinery and equipment where precise control of loads is essential.

- Precision Movement: These bearings provide precise control and movement, making them suitable for applications where accurate positioning of mechanical components is critical. This includes industries like aerospace and robotics.

- Corrosion Resistance: Many rod end bearings are designed with corrosion-resistant materials or coatings, making them suitable for use in harsh environments, such as marine and industrial settings.

- Durability: Rod end bearings are engineered for durability, allowing them to withstand challenging conditions and heavy-duty use. This ensures their reliability and longevity in demanding applications.

- Versatility: Rod end bearings are versatile components used across various industries, including automotive, aerospace, industrial machinery, and marine applications. Their adaptability and reliability make them valuable to engineers and designers.

These design principles and functions of rod end bearings make them indispensable in a wide range of mechanical systems where articulation, load-bearing capacity, and precise control are required.

editor by CX 2024-05-07

China supplier High Precision Combination Connecting Rod End Radial Spherical Plain Joint Ball Bearing ball bearing

Product Description

High Precision Combination Connecting Rod End Radial Spherical Plain Joint Ball Bearing

Product Description

Spherical plain bearing is made up by inner ring and outer ring. The inner ring has a spherical outside surface and the outer ring has inner spherical surface. It can support large load including radial load, axial load or combination load according to the different types and structures. Spherical plain bearing is general used for lower speed swinging motion. Since the sliding surface is spherical, it also can do

tilt movement in certain angle range. Spherical plain bearing resists corrosion and abrasion. And also it has the character of self-aligning, lubrication and self-aligning.It can work well even if in dislocated installation.

Company Profile

HangZhou HONGSHI MACHINERY AND ELECTRICAL EQUIPMENT CO.,LTD. (formerly HangZhou Hengmai Bearing Co., Ltd.) was established in 2007, and HMMH is our own brand.

HMMH mainly produces spherical roller bearings, pillow block ball bearing, deep groove ball bearings and cylindrical roller bearings. Spherical roller bearing products range from 20mm to 1M, with the main production of crusher bearings 22300 series. Low noise deep groove ball bearings, product accuracy can reach ZV2, ZV3, ZV4, mainly produces motor bearings 6200, 6300 series. pillow block ball bearing, mainly producing UCP, UCF, UCFL, UCFC, UCT series, the products are mainly used in agricultural machine and peeling machine. We also use the bainite quenching process to ensure the hardness of the bearing, using good testing equipment, such as roundness meter, profiler, roughness meter, universal measuring instrument, spectrometer, metallographic microscope to control each detail quality monitoring.

To ensure product quality, we have established a strict quality control system and an experienced team of engineers and after-sales service. From forgings to final products we have a strict quality control system.

Your needs are our production motivation, and your satisfaction is our goal. We are willing to serve our customers with the goal of “Quality First, Service First, Credit First”.

FAQ

1.A:How can I do customized design?

Q:We are request for the drawing with the measurement, material and other speicifcation as details as you can, and for the customized products, our MOQ is 10 pcs per design

2.Q: How can I get a sample?

A: If you only need 1or 2 samples for small size inner weight below 2kgs, we can supply free samples and we have stocks, you can just pay the shipping cost .if you need several design samples, then you should paid the cost with shipping.

3.Q: What package do you usually use?

A: Usually we use single box or tape. Also according to customer’s special requirement.

4.Q:How long do you need for production? Or what’s your production lead time?

A:Usually could be sent our in 2-3 days if in stock for samples. Customized item usually need 14-30 days to produce.

5.Q:How long will you guarantee your quality?

A:We supply test report and quality control photos from materials to finished goods during production.

6.Q:How to do after sale service?

A:Good after-sale service is our promise. Before placing orders, our professional engineer will discuss all technical data and your bearing usage condition and CZPT you what kind of steel materials to fit your products and usage life possible.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Contact Angle: | 45° |

|---|---|

| Aligning: | Non-Aligning Bearing |

| Separated: | Unseparated |

| Rows Number: | Single |

| Load Direction: | Axial Bearing |

| Material: | Bearing Steel |

| Customization: |

Available

| Customized Request |

|---|

Differences Between Male and Female Threaded Rod End Bearings

Male and female threaded rod end bearings differ in their design and applications:

Male Threaded Rod End Bearings:

– Male rod end bearings have external threads on the shank or body of the bearing.

– They are typically used in applications where the bearing is mounted to a stationary component, and the threaded shank extends to connect with a mating part (e.g., a linkage or control arm).

– Male rod end bearings allow for easy adjustment or fine-tuning of the connection.

– These bearings are suitable for applications requiring controlled movement or positioning, where the bearing’s external threads facilitate precise adjustments.

Female Threaded Rod End Bearings:

– Female rod end bearings have an internal (female) threaded bore inside the housing.

– They are used when a bolt, stud, or shaft with external threads needs to be connected to the bearing’s housing.

– Female rod end bearings are often employed in applications where the bearing needs to rotate around a fixed shaft or bolt, providing articulation and misalignment capabilities.

– These bearings allow for the attachment of a variety of external components, making them versatile for different applications.

The choice between male and female threaded rod end bearings depends on the specific requirements of the application, including whether the bearing needs to be attached to a stationary part or connected to an external threaded component and the level of adjustability and articulation needed.

Impact of Different Materials on Rod End Bearing Performance

Rod end bearings can be manufactured from various materials, and the choice of material significantly affects their performance. Two common materials used are stainless steel and carbon steel:

Stainless Steel Rod End Bearings:

1. Corrosion Resistance: Stainless steel rod end bearings offer excellent resistance to corrosion, making them suitable for applications in wet or corrosive environments, including marine and outdoor settings.

2. Hygienic Applications: They are ideal for applications in food processing, pharmaceuticals, and medical equipment due to their non-reactive and hygienic properties.

3. Temperature Resistance: Stainless steel can withstand a wide range of temperatures, making these bearings suitable for applications exposed to extreme heat or cold.

Carbon Steel Rod End Bearings:

1. Strength and Durability: Carbon steel rod end bearings are known for their high strength and durability, making them suitable for heavy-duty industrial applications such as construction equipment and agricultural machinery.

2. Cost-Effectiveness: They are often more cost-effective than stainless steel bearings, which makes them a preferred choice when the enhanced corrosion resistance of stainless steel is not required.

3. Machinability: Carbon steel is easier to machine and modify, making it a good choice for customized or specialized bearing configurations.

Ultimately, the choice between stainless steel and carbon steel rod end bearings depends on the specific application’s environmental conditions, load requirements, and cost considerations. Stainless steel is preferred for its corrosion resistance, while carbon steel excels in applications demanding strength and durability.

Rod End Bearings and Their Applications

Rod end bearings, also known as heim joints or rose joints, are mechanical components that consist of a spherical plain bearing with an inner ring and an outer ring. They are widely used in various mechanical applications due to their versatility and ability to provide articulation and movement in different directions. Here are some common applications of rod end bearings:

- Linkages: Rod end bearings are often used in linkages and control systems to transmit motion or force. They provide a connection point between two components, allowing for angular misalignment and smooth movement.

- Automotive Suspension: In automotive applications, rod end bearings are used in suspension systems to connect control arms, sway bars, and other components. They accommodate both rotational and pivoting movement.

- Aerospace: Rod end bearings play a crucial role in aircraft control systems, such as ailerons, flaps, and rudders. They ensure precise and responsive control of the aircraft’s movable surfaces.

- Construction Equipment: Heavy machinery, like cranes and excavators, utilizes rod end bearings in their control systems. These bearings provide flexibility and robustness in handling heavy loads and dynamic forces.

- Industrial Machinery: Various industrial machines, including conveyor systems, manufacturing equipment, and robotic arms, use rod end bearings to enable movement and articulation in mechanical linkages.

- Marine Applications: On boats and ships, rod end bearings are employed in steering and control systems. They withstand the harsh marine environment and provide reliable performance.

- Motion Control Systems: In applications like 3D printers, CNC machines, and robotic arms, rod end bearings are used to create flexible and precise motion control mechanisms.

- Hydraulic Cylinders: Rod end bearings are used in hydraulic cylinders to connect the piston rod to the external components. They allow for both linear motion and misalignment.

- Off-Road Vehicles: In off-road vehicles such as ATVs and dirt bikes, rod end bearings are used in suspension systems to absorb shocks and provide articulation over rough terrain.

Rod end bearings are valued for their ability to handle both static and dynamic loads, accommodate misalignment, and offer long-lasting performance in a wide range of applications.

editor by CX 2024-05-07

China Custom Ge 200 Es 2RS Radial Spherical Plain Bearing Ge200es Size 200X290X130mm Rod End Joint Bearing Ge200 Ge200es-2RS double row ball bearing

Product Description

GEG230XS-2RS Ball Joint Bearing Radial Spherical Plain Bearing GEG 230 XS-2RS-L571

GE Series Radial Spherical Plain Bearing

| Product Name | Spherical Plain Bearing |

| Precision Rating | P6, P0, P5, P4, P2 |

| Material | Bearing Steel (GCr15) |

| Clearance | C0 C1 C2 C3 C4 C5 |

| Vibration & Noisy | Z1,Z2,Z3 V1,V2,V3 |

| Sliding Contact | Steel-on-Steel |

| Features | High Precision, High Speed, Long Life, High Reliability, Low Noise , Reduce Friction |

| Certification | ISO 9001:2008 |

| Packing | 1.Neutral Packing Bearing 2.Industrial Packing 3.Commercial Packing Bearing 4.Customize |

| Delivery Time | 30 – 45 Days After The Order is Confirmed |

| Shippment | 1.By Sea 2.By Air 3.By Express |

Product Description

| Bearing No. | Dimensions(mm) | Load ratings KN |

a° ≈ |

weight ≈ kg |

|||||||

| d | D | B | c | dk | rs | r1s | Dynamic | Static | |||

| GE15ES-2RS | 15 | 26 | 12 | 9 | 22 | 0.3 | 0.3 | 16 | 84 | 8 | 0.571 |

| GE17ES-2RS | 17 | 30 | 14 | 10 | 25 | 0.3 | 0.3 | 21 | 106 | 10 | 0.041 |

| GE20ES-2RS | 20 | 35 | 16 | 12 | 29 | 0.3 | 0.3 | 30 | 146 | 9 | 0.066 |

| GE25ES-2RS | 25 | 42 | 20 | 16 | 35.5 | 0.6 | 0.6 | 48 | 240 | 7 | 0.119 |

| GE30ES-2RS | 30 | 47 | 22 | 18 | 40.7 | 0.6 | 0.6 | 62 | 310 | 6 | 0.153 |

| GE35ES-2RS | 35 | 55 | 25 | 20 | 47 | 0.6 | 1 | 79 | 399 | 6 | 0.233 |

| GE40ES-2RS | 40 | 62 | 28 | 22 | 53 | 0.6 | 1 | 99 | 495 | 7 | 0.306 |

| GE45ES-2RS | 45 | 68 | 32 | 25 | 60 | 0.6 | 1 | 127 | 637 | 7 | 0.427 |

| GE50ES-2RS | 50 | 75 | 35 | 28 | 66 | 0.6 | 1 | 156 | 780 | 6 | 0.546 |

| GE55ES-2RS | 55 | 85 | 40 | 32 | 74 | 0.6 | 1 | 200 | 1000 | 7 | 0.939 |

| GE60ES-2RS | 60 | 90 | 44 | 36 | 80 | 1 | 1 | 245 | 1220 | 6 | 1.04 |

| GE70ES-2RS | 70 | 105 | 49 | 40 | 92 | 1 | 1 | 313 | 1560 | 6 | 1.55 |

| GE80ES-2RS | 80 | 120 | 55 | 45 | 105 | 1 | 1 | 400 | 2000 | 6 | 2.31 |

| GE90ES-2RS | 90 | 130 | 60 | 50 | 115 | 1 | 1 | 488 | 2440 | 5 | 2.75 |

| GE100ES-2RS | 100 | 150 | 70 | 55 | 130 | 1 | 1 | 607 | 3030 | 7 | 4.45 |

| GE110ES-2RS | 110 | 160 | 70 | 55 | 140 | 1 | 1 | 654 | 3270 | 6 | 4.82 |

| GE120ES-2RS | 120 | 180 | 85 | 70 | 160 | 1 | 1 | 950 | 4750 | 6 | 8.05 |

| GE140ES-2RS | 140 | 210 | 90 | 70 | 180 | 1 | 1 | 1070 | 5350 | 7 | 11.02 |

| GE160ES-2RS | 160 | 230 | 105 | 80 | 200 | 1 | 1 | 1360 | 6800 | 8 | 14.01 |

| GE180ES-2RS | 180 | 260 | 105 | 80 | 225 | 1.1 | 1.1 | 1530 | 7650 | 6 | 18.65 |

| GE200ES-2RS | 200 | 290 | 130 | 100 | 250 | 1.1 | 1.1 | 2120 | 10600 | 7 | 28.03 |

| GE220ES-2RS | 220 | 320 | 135 | 100 | 275 | 1.1 | 1.1 | 2320 | 11600 | 8 | 35.51 |

| GE240ES-2RS | 240 | 340 | 140 | 100 | 300 | 1.1 | 1.1 | 2550 | 12700 | 8 | 39.91 |

| GE260ES-2RS | 260 | 370 | 150 | 110 | 325 | 1.1 | 1.1 | 3030 | 15190 | 7 | 51.54 |

| GE280ES-2RS | 280 | 400 | 155 | 120 | 350 | 1.1 | 1.1 | 3570 | 17850 | 6 | 65.06 |

| GE300ES-2RS | 300 | 430 | 165 | 120 | 375 | 1.1 | 1.1 | 3800 | 19100 | 7 | 78.07 |

Detailed Photos

Classification

Our company has a large inventory with thousands of bearings in stock. They are widely used in all kinds of machinery in various fields, like mechanical equipment, electric power equipment, machine tool, auto, construction machinery, road engineering machinery, etc.

Our products are mainly exported to Singapore, South Korea, Vietnam, Thailand, Turkey, Pakistan, Australia, Poland, France, the UK, South Africa, the USA, South America, and other countries and regions all over the world. Our company is highly appreciated by our customers both at home and abroad due to high quality and reasonable price. We are always dedicated to building long-term business relationships with our old customers through good products and services. We sincerely hope that domestic and foreign friends come to create a brilliant future together with us and we are always at your service.

Company Profile

Packaging & Shipping

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.We have our own brand:HQA .If you interested in our product,I can take you to visit our factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Where is your factory located? How can I visit there?

A: Our factory is located in ZheJiang Province,You can take the high-speed rail or plane to visit.

Q: Do you provide samples ? it is free charge?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q:The MOQ is how much?

A: About ordinary standard type of bearing ,We have rich inventory,not have MOQ,if your need a

product is Non-standard size,need customize,we will according the product size to determine the MOQ.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Contact Angle: | 0 |

|---|---|

| Aligning: | Non-Aligning Bearing |

| Separated: | Separated |

| Rows Number: | Single |

| Material: | Gcr15 |

| Type: | Sliding Bearings |

| Samples: |

US$ 0.01/Set

1 Set(Min.Order) | |

|---|

Recent Advancements in Rod End Bearing Technology

Advancements in rod end bearing technology have led to improved performance and durability. Here are some insights into recent developments:

1. Enhanced Materials: Manufacturers are using advanced materials, including high-strength alloys and composites, to create rod end bearings that offer increased load-carrying capacity and improved corrosion resistance. These materials contribute to longer bearing life and better performance in challenging environments.

2. Sealing and Shielding: Innovations in sealing and shielding technologies have improved the protection of rod end bearings from contaminants, moisture, and harsh environmental conditions. These advancements extend maintenance intervals and increase bearing reliability.

3. Lubrication: Self-lubricating rod end bearings have become more prevalent, reducing the need for frequent manual lubrication. These bearings are designed to provide consistent and long-lasting lubrication, resulting in reduced maintenance requirements and longer service life.

4. 3D Modeling and Simulation: Manufacturers are increasingly using 3D modeling and simulation techniques to optimize rod end bearing designs. This allows for the creation of bearings that can handle higher loads and offer superior wear resistance while maintaining compact dimensions.

5. Customization: The ability to customize rod end bearings to specific application requirements has improved. This includes options for different thread types, materials, and sizes. Customization ensures that the bearing can meet the exact needs of the equipment it serves.

6. Environmental Sustainability: Some recent advancements focus on producing rod end bearings in an environmentally sustainable manner. Manufacturers are exploring eco-friendly materials and production processes to reduce the environmental impact of bearing manufacturing.

7. IoT Integration: In industrial applications, the integration of Internet of Things (IoT) technology allows for real-time monitoring and predictive maintenance of rod end bearings. Sensors and data analytics help detect early signs of wear or damage, optimizing maintenance schedules and minimizing downtime.

These recent advancements in rod end bearing technology have collectively improved the reliability, durability, and performance of these components in various mechanical systems. As technology continues to evolve, rod end bearings are expected to play an even more critical role in enhancing the efficiency and longevity of machinery and equipment.

Impact of Different Materials on Rod End Bearing Performance

Rod end bearings can be manufactured from various materials, and the choice of material significantly affects their performance. Two common materials used are stainless steel and carbon steel:

Stainless Steel Rod End Bearings:

1. Corrosion Resistance: Stainless steel rod end bearings offer excellent resistance to corrosion, making them suitable for applications in wet or corrosive environments, including marine and outdoor settings.

2. Hygienic Applications: They are ideal for applications in food processing, pharmaceuticals, and medical equipment due to their non-reactive and hygienic properties.

3. Temperature Resistance: Stainless steel can withstand a wide range of temperatures, making these bearings suitable for applications exposed to extreme heat or cold.

Carbon Steel Rod End Bearings:

1. Strength and Durability: Carbon steel rod end bearings are known for their high strength and durability, making them suitable for heavy-duty industrial applications such as construction equipment and agricultural machinery.

2. Cost-Effectiveness: They are often more cost-effective than stainless steel bearings, which makes them a preferred choice when the enhanced corrosion resistance of stainless steel is not required.

3. Machinability: Carbon steel is easier to machine and modify, making it a good choice for customized or specialized bearing configurations.

Ultimately, the choice between stainless steel and carbon steel rod end bearings depends on the specific application’s environmental conditions, load requirements, and cost considerations. Stainless steel is preferred for its corrosion resistance, while carbon steel excels in applications demanding strength and durability.

Rod End Bearings and Their Applications

Rod end bearings, also known as heim joints or rose joints, are mechanical components that consist of a spherical plain bearing with an inner ring and an outer ring. They are widely used in various mechanical applications due to their versatility and ability to provide articulation and movement in different directions. Here are some common applications of rod end bearings:

- Linkages: Rod end bearings are often used in linkages and control systems to transmit motion or force. They provide a connection point between two components, allowing for angular misalignment and smooth movement.