Product Description

Product Description

Information:

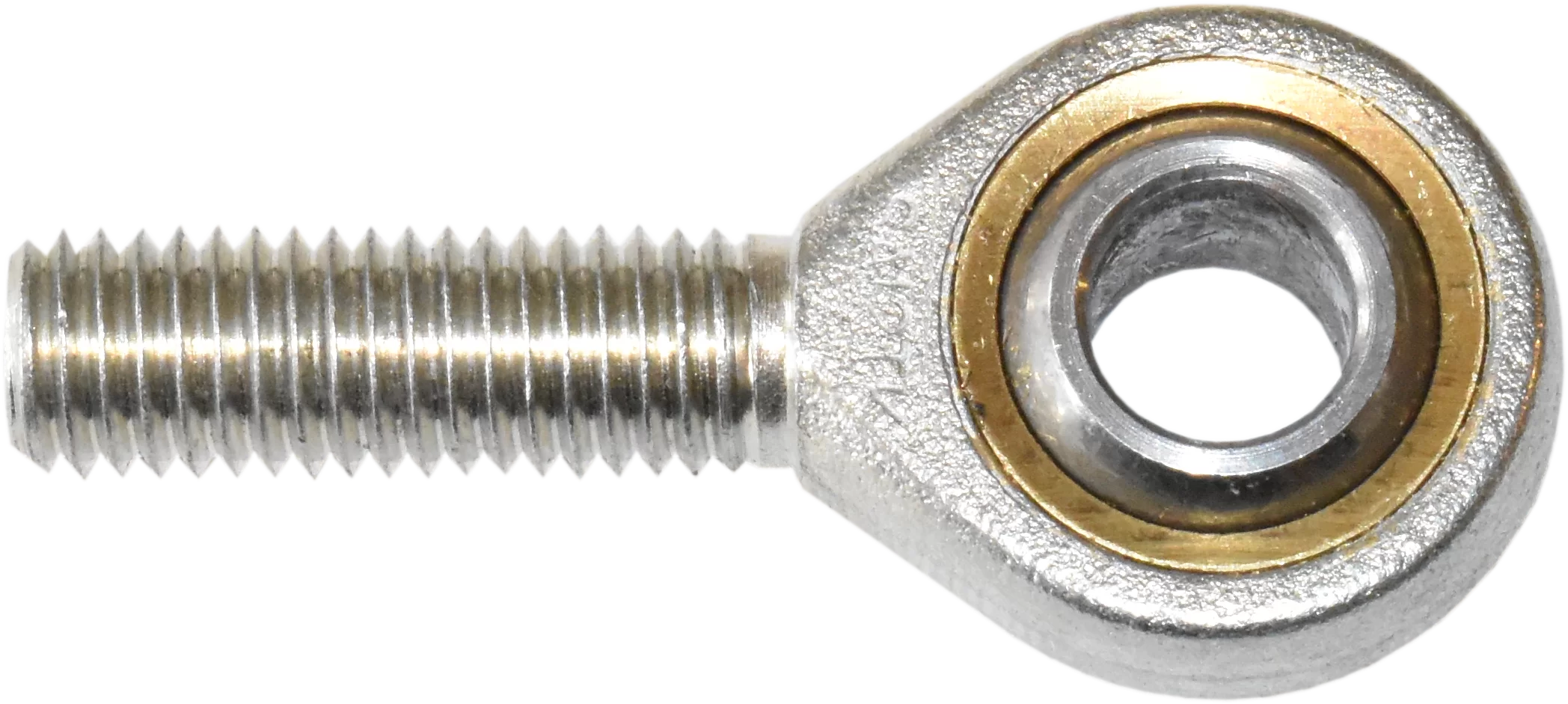

TheSpherical Plain Bearing is mainly composed of an inner ring with an outer sphere and an outer ring with an inner sphere. The joint bearing is generally used for low-speed swing motion (i.e. angular motion). Because the sliding surface is spherical, it can also make inclined motion (i.e. centering motion) within a certain angle range. It can still work normally when the concentricity between the support shaft and the shaft shell hole is large

Feature:

The plain bearing can bear large load. According to its different types and structures, it can bear radial load, axial load or combined radial and axial load at the same time. Because the outer spherical surface of the inner ring is inlaid with CZPT materials, the bearing can produce self lubrication in operation. It is generally used for low-speed swing movement and low-speed rotation. It can also make inclined movement within a certain angle range. It can still work normally when the non concentricity between the support shaft and the shaft shell hole is large. Self lubricating plain bearings are used in water conservancy, professional machinery and other industries

Detailed Photos

Product Parameters

| Model | Dimensions (mm) | Load ratings(KN) | Mass | ||||||||

| d | D | B | C | dk | r1 | r2 | C | C0 | kg | ||

| min | min | ||||||||||

| GE15ES | 15 | 26 | 12 | 9 | 22 | 0.3 | 0.3 | 8 | 16 | 84 | 0.571 |

| GE17ES | 17 | 30 | 14 | 10 | 25 | 0.3 | 0.3 | 10 | 21 | 106 | 0.041 |

| GE20ES | 20 | 35 | 16 | 12 | 29 | 0.3 | 0.3 | 9 | 30 | 146 | 0.066 |

| GE25ES | 25 | 42 | 20 | 16 | 35.5 | 0.6 | 0.6 | 7 | 48 | 240 | 0.119 |

| GE30ES | 30 | 47 | 22 | 18 | 40.7 | 0.6 | 0.6 | 6 | 62 | 310 | 0.153 |

| GE35ES | 35 | 55 | 25 | 20 | 47 | 0.6 | 1 | 6 | 79 | 399 | 0.233 |

| GE40ES | 40 | 62 | 28 | 22 | 53 | 0.6 | 1 | 7 | 99 | 495 | 0.306 |

| GE45ES | 45 | 68 | 32 | 25 | 60 | 0.6 | 1 | 7 | 127 | 637 | 0.427 |

| GE50ES | 50 | 75 | 35 | 28 | 66 | 0.6 | 1 | 6 | 156 | 780 | 0.546 |

| GE60ES | 60 | 90 | 44 | 36 | 80 | 1 | 1 | 6 | 245 | 1220 | 1.04 |

| GE70ES | 70 | 105 | 49 | 40 | 92 | 1 | 1 | 6 | 313 | 1560 | 1.55 |

| GE80ES | 80 | 120 | 55 | 45 | 105 | 1 | 1 | 6 | 400 | 2000 | 2.31 |

| GE90ES | 90 | 130 | 60 | 50 | 115 | 1 | 1 | 5 | 488 | 2440 | 2.75 |

| GE100ES | 100 | 150 | 70 | 55 | 130 | 1 | 1 | 7 | 607 | 3030 | 4.45 |

| GE110ES | 110 | 160 | 70 | 55 | 140 | 1 | 1 | 6 | 654 | 3270 | 4.82 |

| GE120ES | 120 | 180 | 85 | 70 | 160 | 1 | 1 | 6 | 950 | 4750 | 8.05 |

| GE140ES | 140 | 210 | 90 | 70 | 180 | 1 | 1 | 7 | 1070 | 5350 | 11.02 |

| GE160ES | 160 | 230 | 105 | 80 | 200 | 1 | 1 | 8 | 1360 | 6800 | 14.01 |

| GE180ES | 180 | 260 | 105 | 80 | 225 | 1.1 | 1.1 | 6 | 1530 | 7650 | 18.65 |

| GE200ES | 200 | 290 | 130 | 100 | 250 | 1.1 | 1.1 | 7 | 2120 | 10600 | 28.03 |

| GE220ES | 220 | 320 | 135 | 100 | 275 | 1.1 | 1.1 | 8 | 2320 | 11600 | 35.51 |

| GE240ES | 240 | 340 | 140 | 100 | 300 | 1.1 | 1.1 | 8 | 2550 | 12700 | 39.91 |

GE4E GEG4E GEEW12ES GEEM20ES-2RS

GE5E GEG5E GEEW15ES GEEM25ES-2RS

GE6E GEG6E GEEW16ES GEEM30ES-2RS

GE8E GEG8E GEEW17ES GEEM35ES-2RS

GE10E GEG10E GEEW20ES GEEM40ES-2RS

GE12E GEG12E GEEW25ES GEEM45ES-2RS

GE15ES GE15ES-2RS GEG15ES GEG15ES-2RS GEEW30ES GEEM50ES-2RS

GE17ES GE17ES-2RS GEG17ES GEG17ES-2RS GEEW32ES GEEM55ES-2RS

GE20ES GE20ES-2RS GEG20ES GEG20ES-2RS GEEW35ES GEEM60ES-2RS

GE25ES GE25ES-2RS GEG25ES GEG25ES-2RS GEEW40ES GEEM70ES-2RS

GE30ES GE30ES-2RS GEG30ES GEG30ES-2RS GEEW45ES GEEM80ES-2RS

GE35ES GE35ES-2RS GEG35ES GEG35ES-2RS GEEW50ES GEEM90ES-2RS

GE40ES GE40ES-2RS GEG40ES GEG40ES-2RS GEEW60ES GEEM100ES-2RS

GE45ES GE45ES-2RS GEG45ES GEG45ES-2RS GEEW63ES GEEM110ES-2RS

GE50ES GE50ES-2RS GEG50ES GEG50ES-2RS GEEW70ES GEEM120ES-2RS

GE55ES GE55ES-2RS GEG55ES GEG55ES-2RS GEEW80ES

GE60ES GE60ES-2RS GEG60ES GEG60ES-2RS GEEW90ES

GE70ES GE70ES-2RS GEG70ES GEG70ES-2RS GEEW100ES

GE80ES GE80ES-2RS GEG80ES GEG80ES-2RS GEEW110ES

GE90ES GE90ES-2RS GEG90ES GEG90ES-2RS GEEW125ES

GE100ES GE100ES-2RS GEG100ES GEG100ES-2RS GEEW160ES

GE110ES GE110ES-2RS GEG110ES GEG110ES-2RS GEEW200ES

GE120ES GE120ES-2RS GEG120ES GEG120ES-2RS GEEW250ES

GE140ES GE140ES-2RS GEG140ES GEG140ES-2RS GEEW320ES

GE160ES GE160ES-2RS GEG160ES GEG160ES-2RS

GE180ES GE180ES-2RS GEG180ES GEG180ES-2RS

GE200ES GE200ES-2RS GEG200ES GEG200ES-2RS

GE220ES GE220ES-2RS

GE240ES GE240ES-2RS

GE260ES GE260ES-2RS

GE280ES GE280ES-2RS

GE300ES GE300ES-2RS

Packaging & Shipping

Company Profile

Our Advantages

Our Advantages:

1. World-Class Bearing: We provide our customers with all types of indigenous bearing with world-class quality.

2. OEM or Non-Stand Bearings: Any requirement for Nonstandard bearings is Easily Fulfilled by us due to its vast knowledge and links in the industry.

3. Genuine products With Excellent Quality: The company has always proved the 100% quality products it provides with genuine intent.

4. After Sales Service and Technical Assistance: The company provides after-sales service and technical assistance as per the customer’s requirements and needs.

5. Quick Delivery: The company provides just-in-time delivery with its streamlined supply chain.

SAMPLES

1. Samples quantity: 1-10 PCS are available.

2. Free samples: It depends on the Model No., material and quantity. Some of the bearings samples need client to

pay samples charge and shipping cost.

3. It’s better to start your order with Trade Assurance to get full protection for your samples order.

CUSTOMIZED

The customized LOGO or drawing is acceptable for us.

MOQ

1. MOQ: 10 PCS standard bearings.

2. MOQ: 1000 PCS customized your brand bearings.

OEM POLICY

1. We can printing your brand (logo, artwork)on the shield or laser engraving your brand on the shield.

2. We can custom your packaging according to your design

3. All copyright own by clients and we promised don’t disclose any info.

FAQ

1.What is the minimum order quantity for this product?

Can be negotiated, we will try our best to meet customer needs.Our company is mainly based on wholesale sales,

most customers’orders are more than 1 ton.

2.What is your latest delivery time?

Most orders will be shipped within 7-15 days of payment being received.

3.Does your company have quality assurance?

Yes, for 1 years.

4.What is the competitiveness of your company’s products compared to other companies?

High precision, high speed, low noise.

5.What are the advantages of your company’s services compared to other companies?

Answer questions online 24 hours a day, reply in a timely manner, and provide various documents required by

customers for customs clearance or sales. 100% after-sales service.

6.Which payment method does your company support?

Do our best to meet customer needs, negotiable.

7.How to contact us quickly?

Please send us an inquiry or message and leave your other contact information, such as phone number,

account or account, we will contact you as soon as possible and provide the detailed information you need.

Please feel free to contact us, if you have any other question

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Rolling Element: | Single Row |

|---|---|

| Structure: | To The Heart |

| Material: | Bearing Steel |

| Load Direction: | Radial Spherical Plain Bearing |

| Add Lubricant: | Self-lubricating |

| Outer Structure: | Whole Outer Ring |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Improving Aircraft Functionality with Rod End Bearings

Rod end bearings play a critical role in enhancing the functionality and safety of various aircraft components, including control surfaces and landing gear. Here’s how:

Aircraft Control Surfaces:

Rod end bearings are commonly used in aircraft control systems to connect control surfaces, such as ailerons, elevators, and rudders, to control cables or rods. These bearings provide several key benefits:

- Articulation: Rod end bearings offer articulation capabilities, allowing control surfaces to move smoothly and precisely. This flexibility is essential for pilots to control the aircraft’s attitude, roll, pitch, and yaw.

- Misalignment Compensation: Aircraft structures experience various forces and vibrations during flight. Rod end bearings accommodate misalignment, ensuring that control systems remain effective even under dynamic conditions.

- Durability: Aircraft operate in challenging environments, and rod end bearings are designed to withstand extreme temperatures, vibrations, and mechanical stress. Their robust construction contributes to the longevity and reliability of control systems.

- Weight Savings: Aircraft design prioritizes weight reduction. Rod end bearings, typically made from lightweight materials like high-strength alloys or composites, help minimize the overall weight of the aircraft.

Landing Gear:

Rod end bearings are also utilized in landing gear systems, which are critical for safe takeoffs, landings, and ground operations. Their contributions include:

- Shock Absorption: Landing gear components, including rod end bearings, play a role in shock absorption during landing, reducing the impact forces transmitted to the aircraft’s structure and passengers.

- Articulation for Retraction and Extension: Rod end bearings enable the controlled movement of landing gear components, allowing for smooth retraction and extension. This is crucial for aerodynamic efficiency and safety.

- Structural Integrity: Rod end bearings help maintain the structural integrity of the landing gear assembly, ensuring that it can support the aircraft’s weight during ground operations.

Overall, rod end bearings in aircraft applications contribute to the precise control, safety, and structural reliability necessary for aviation. Their ability to handle articulation, misalignment, and challenging operating conditions makes them indispensable components in the aerospace industry.

Contribution of Rod End Bearings to Smooth Movement in Automotive Control Systems

Rod end bearings play a crucial role in ensuring the smooth movement of control systems in various automotive applications. Here’s how they contribute:

1. Steering Systems:

Rod end bearings are used in steering linkages and tie rod ends. They provide the necessary articulation and pivoting to allow the front wheels to turn smoothly, enabling precise steering control. The low friction and high load-bearing capacity of rod end bearings contribute to responsive and accurate steering in both manual and power steering systems.

2. Suspension Systems:

In suspension systems, rod end bearings are used in components like control arms and stabilizer links. They allow for controlled movement of the suspension, ensuring that the vehicle’s wheels maintain optimal contact with the road surface. This contributes to a smoother and more comfortable ride, improved handling, and better traction, especially when driving over uneven or bumpy terrain.

3. Throttle and Accelerator Linkages:

Rod end bearings are employed in throttle and accelerator linkages, where they assist in transmitting pedal inputs to the engine’s throttle body. The smooth articulation provided by rod end bearings ensures that drivers can easily modulate engine power, contributing to smooth acceleration and deceleration.

4. Gear Shift Linkages:

In manual transmissions, rod end bearings are used in gear shift linkages. They enable precise and smooth gear changes by allowing for the controlled movement of the shift lever. This ensures that gears engage smoothly, reducing drivetrain shock and vibration.

5. Convertible Roof Mechanisms:

In convertible cars, rod end bearings are used in the mechanisms that operate the folding and unfolding of the convertible roof. The smooth articulation of rod end bearings contributes to the seamless transition between open and closed roof positions, enhancing the overall driving experience.

Overall, rod end bearings are integral components in automotive control systems, ensuring the smooth and precise operation of various critical functions, including steering, suspension, throttle control, gear shifting, and convertible roof movement.

Impact of Proper Lubrication on Rod End Bearings

Proper lubrication is crucial for enhancing the performance and extending the longevity of rod end bearings. Here’s how it impacts these aspects:

1. Reduced Friction: Lubrication creates a film between moving parts, reducing friction. This minimizes wear and heat generation, leading to smoother and more efficient operation of the rod end bearing.

2. Wear Prevention: Lubrication helps prevent wear and surface damage on bearing components, particularly the ball and raceway. This is vital for the long-term durability of the bearing.

3. Corrosion Resistance: In applications exposed to moisture or corrosive substances, lubrication provides a protective barrier, preventing rust and corrosion on the bearing’s surfaces. This is especially important in outdoor or marine environments.

4. Noise Reduction: Adequate lubrication reduces noise and vibration in the bearing. This is important for applications where noise levels must be minimized, such as in the aerospace or medical industries.

5. Temperature Control: Lubrication helps dissipate heat generated by friction. Effective temperature control prevents overheating, which can lead to premature bearing failure.

6. Seal and Shield Function: Lubrication also works in conjunction with bearing seals and shields to keep contaminants out. It maintains a clean and contaminant-free internal environment, further increasing the bearing’s longevity.

7. Longevity: Proper lubrication significantly extends the service life of rod end bearings. Regular maintenance and relubrication schedules are essential for maximizing the bearing’s operational lifespan.

8. Efficiency: Lubrication contributes to the overall efficiency of the bearing, ensuring that it operates at peak performance levels, even under heavy loads or misalignment conditions.

9. Performance Consistency: Adequate lubrication helps maintain consistent performance over time. This is especially important in critical applications where performance fluctuations could lead to safety or quality concerns.

It’s important to use the lubricant recommended by the bearing manufacturer and follow their guidelines for lubrication intervals. Over-lubrication can be as detrimental as under-lubrication, so maintaining the right balance is essential.

Regular inspections and maintenance routines should be established to monitor the lubrication condition and reapply lubricant as needed. This proactive approach ensures that rod end bearings operate effectively, offering reliability and a longer service life.

editor by CX 2024-04-16