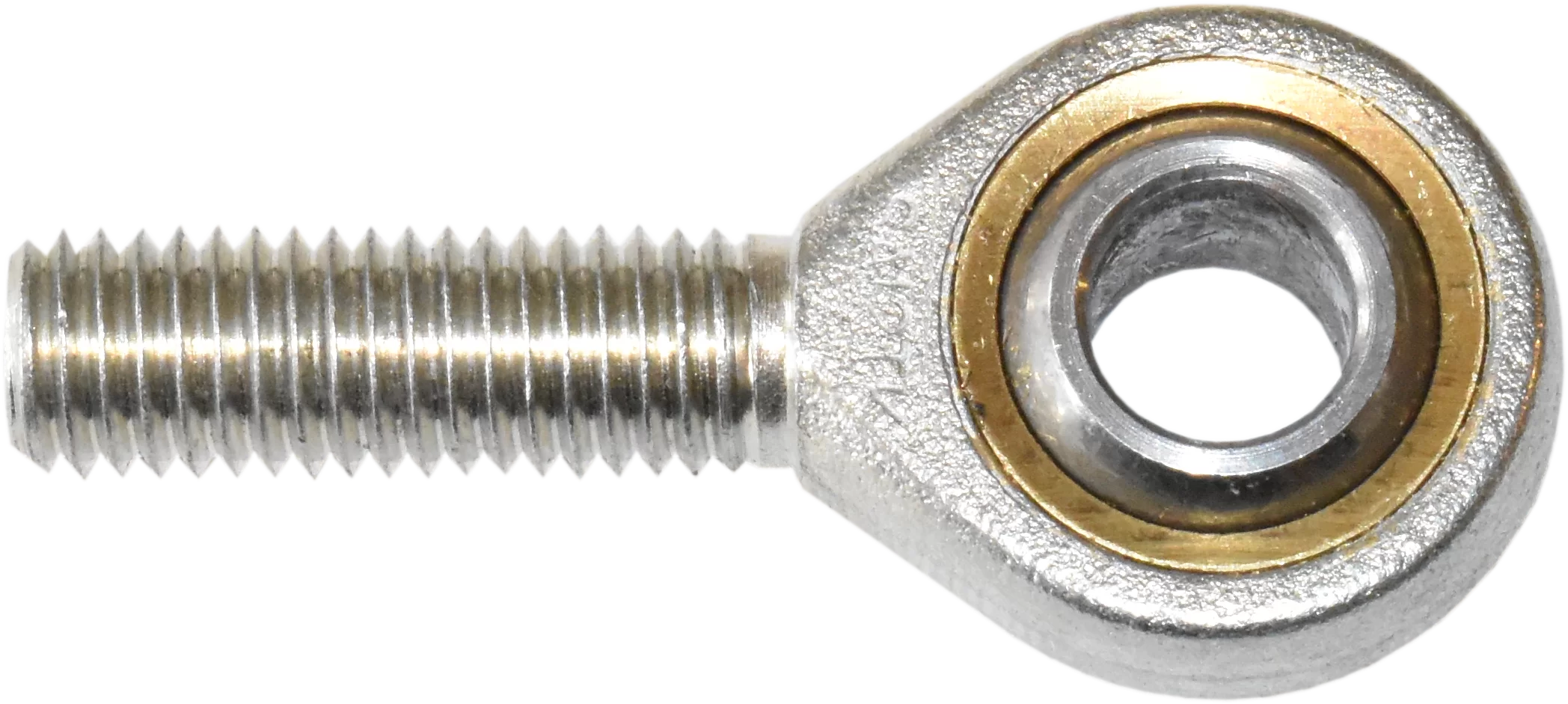

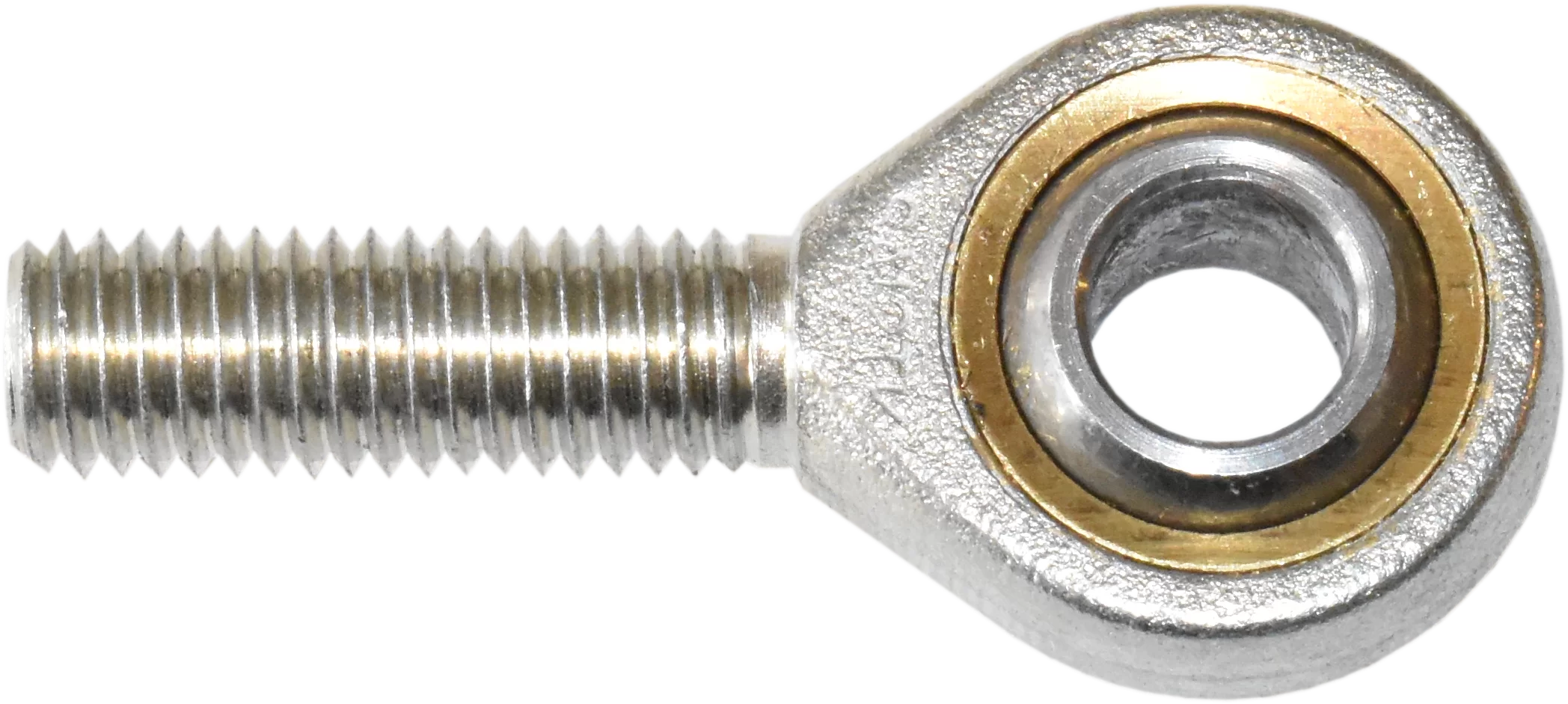

Product Description

BRF5 BRF5-1 BRF6 BRF8 BRF10 BRF10-1 BRF12 BRF12-1 BRF14 BRF14-1 BRF16 BRF16-1 BRF18 BRF20 BRF22 BRF25 BRF30 BRF30-1 BRF35 BRF40 BRF50 BRM5 BRM6 BRM8 BRM10 BRM12 BRM14 BRM16 BRM18 BRM20 BRM22 BRM25 BRM30 BRM35 BRM40 BRM50 POS3 POS4 POS5 POS6 POS8 POS10 POS12 POS14 POS16 POS18 POS20 POS22 POS25 POS28 POS30 CF3 CF4 CF5 CF6 CF7 CF8 CF10 CF12 CM3 CM4 CM5 CM6 CM7 CM8 CM10 CM12 CF3Y CF4Y CF5Y CF6Y CF7Y CF8Y CF10Y CF12Y CM3Y CM4Y CM5Y CM6Y CM7Y CM8Y CM10Y CM12Y KF20-1 KF24-1 KF32-1 KM20-1 KM24-1 KM32-1 SI5C SI6C SI8C SI10C SI12C SI15C SI17C SI20C SI25C SI30C SI15ET2RS SI17ET2RS SI20ET2RS SI25ET2RS SI30ET2RS SI35ET2RS SI40ET2RS SI45ET2RS SI50ET2RS SI60ET2RS SI70ET2RS SI80ET2RS SA15ET2RS SA17ET2RS SA20ET2RS SA25ET2RS SA30ET2RS SA35ET2RS SA40ET2RS SA45ET2RS SA50ET2RS SA60ET2RS SA70ET2RS SA80ET2RS SIG4C SIG5C SIG6C SIG8C SIG10C SIG12C SIG15C SIG17C SIG20C SIG25C SIG30C SIG15ET2RS SIG17ET2RS SIG20ET2RS SIG25ET2RS SIG30ET2RS SIG35ET2RS SIG40ET2RS SIG45ET2RS SIG50ET2RS SIG60ET2RS SIG70ET2RS SAG4C SAG5C SAG6C SAG8C SAG10C SAG12C SAG15C SAG17C SAG20C SAG25C SAG30C SAG15ET2RS SAG17ET2RS SAG20ET2RS SAG25ET2RS SAG30ET2RS SAG35ET2RS SAG40ET2RS SAG45ET2RS SAG50ET2RS SAG60ET2RS SAG70ET2RS SI3T SI4T SA2T SA3T SA4T NHS3T NHS4T NHS5T NHS6T NHS8T NHS10T NHS12T NHS14T NHS16T NHS18T NHS20T NHS22T NHS25T NHS28T NHS30T NOS3T NOS4T NOS5T NOS6T NOS8T NOS10T NOS12T NOS14T NOS16T NOS18T NOS20T NOS22T NOS25T NOS28T NOS30T CF5T CF6T CF7T CF8T CF10T CF12T CM5T CM6T CM7T CM8T CM10T CM12T JF2 JF3 JF4 JF5 JF6 JF7 JF8 JF10 JF12 JF14 JF14-1 JF16 JF16-1 JF16-2 JM2 JM3 JM4 JM5 JM6 JM7 JM8 JM10 JM12 JM14 JM14-1 JM16 JM16-1 JM16-2 XF-3 XF-4 XF-4 XF-5 XF-6 XF-7 XF-8 XF-10 XF-12 XFL-3 XFL-4 XFL-5 XFL-6 XFL-7 XFL-8 XFL-10 XFL-12 XM-3 XM-4 XM-5 XM-6 XM-7 XM-8 XM-10 XM-12 XM-16 XML-3 XML-4 XML-5 XML-6 XML-7 XML-8 XML-10 XML-12 XML-16 SIQ5TK SIQ6TK SIQ8TK SIQ10TK SIQ12TK SIQ14TK SIQ16TK SIQ18TK SIQ20TK SIQ22TK SIQ24TK SIQ30TK SAQ5TK SAQ6TK SAQ8TK SAQ10TK SAQ12TK SAQ14TK SAQ16TK SAQ18TK SAQ20TK SAQ22TK SAQ24TK SAQ30TK PHSQ5 PHSQ6 PHSQ8 PHSQ10 PHSQ10-1 PHSQ12 PHSQ12-1 PHSQ14 PHSQ14-1 PHSQ16 PHSQ16-1 PHSQ18 PHSQ20 PHSQ22 PHSQ25 PHSQ30 POSQ5 POSQ6 POSQ8 POSQ10 POSQ12 POSQ14 POSQ16 POSQ18 POSQ20 POSQ22 POSQ25 POSQ30 BLm6*1 BLm8*1.25 BLm10*1.5 BLm10*1.25 BLm12*1.75 BLm12*1.25 BLm16*2 BLm16*1.5 CS8 CS10 CS13 CS16 CS16-1 CS19 CS19-1

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Rolling Element: | Single Row |

|---|---|

| Structure: | Rod End |

| Material: | Stainless Steel |

| Load Direction: | Radial Spherical Plain Bearing |

| Add Lubricant: | Self-lubricating |

| Outer Structure: | Outer Ring of Single-Slit |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Improving Aircraft Functionality with Rod End Bearings

Rod end bearings play a critical role in enhancing the functionality and safety of various aircraft components, including control surfaces and landing gear. Here’s how:

Aircraft Control Surfaces:

Rod end bearings are commonly used in aircraft control systems to connect control surfaces, such as ailerons, elevators, and rudders, to control cables or rods. These bearings provide several key benefits:

- Articulation: Rod end bearings offer articulation capabilities, allowing control surfaces to move smoothly and precisely. This flexibility is essential for pilots to control the aircraft’s attitude, roll, pitch, and yaw.

- Misalignment Compensation: Aircraft structures experience various forces and vibrations during flight. Rod end bearings accommodate misalignment, ensuring that control systems remain effective even under dynamic conditions.

- Durability: Aircraft operate in challenging environments, and rod end bearings are designed to withstand extreme temperatures, vibrations, and mechanical stress. Their robust construction contributes to the longevity and reliability of control systems.

- Weight Savings: Aircraft design prioritizes weight reduction. Rod end bearings, typically made from lightweight materials like high-strength alloys or composites, help minimize the overall weight of the aircraft.

Landing Gear:

Rod end bearings are also utilized in landing gear systems, which are critical for safe takeoffs, landings, and ground operations. Their contributions include:

- Shock Absorption: Landing gear components, including rod end bearings, play a role in shock absorption during landing, reducing the impact forces transmitted to the aircraft’s structure and passengers.

- Articulation for Retraction and Extension: Rod end bearings enable the controlled movement of landing gear components, allowing for smooth retraction and extension. This is crucial for aerodynamic efficiency and safety.

- Structural Integrity: Rod end bearings help maintain the structural integrity of the landing gear assembly, ensuring that it can support the aircraft’s weight during ground operations.

Overall, rod end bearings in aircraft applications contribute to the precise control, safety, and structural reliability necessary for aviation. Their ability to handle articulation, misalignment, and challenging operating conditions makes them indispensable components in the aerospace industry.

Maintenance Practices to Extend the Life of Rod End Bearings

Rod end bearings play a crucial role in various mechanical systems, and proper maintenance can significantly extend their lifespan. Here are some specific maintenance practices to consider:

1. Lubrication: Regularly lubricate the rod end bearing according to the manufacturer’s recommendations. Proper lubrication reduces friction, minimizes wear, and prevents corrosion. Use high-quality lubricants suitable for the application’s conditions.

2. Inspection: Perform routine inspections to check for signs of wear, damage, or contamination. Look for play, unusual noises, visible damage, and any other indicators mentioned earlier. Timely detection of issues allows for prompt corrective action.

3. Cleanliness: Keep the surrounding environment clean to prevent contamination. Dust, dirt, and debris can lead to premature wear and damage. Regularly clean the bearing housing and sealing mechanisms.

4. Environmental Protection: In applications exposed to harsh environments, consider protective measures such as seals and shields to prevent contamination and reduce exposure to moisture, dust, or chemicals.

5. Alignment: Ensure proper alignment of rod end bearings within the system. Misalignment can increase stress on the bearing and lead to premature failure. Correct any alignment issues promptly.

6. Avoid Overloading: Be mindful of load capacities and avoid subjecting rod end bearings to excessive loads. Overloading can lead to rapid wear and shortened bearing life. Use bearings with appropriate load ratings for the application.

7. Regular Maintenance Schedule: Establish a maintenance schedule that includes lubrication, inspections, and cleaning. The frequency of maintenance depends on factors like operating conditions, load, and the manufacturer’s recommendations.

8. Replacement of Seals: If your rod end bearings have seals or shields, periodically check their condition. Replace damaged or worn-out seals to maintain effective contamination protection.

9. Storage: When storing spare rod end bearings, ensure they are kept in a clean, dry, and temperature-controlled environment. Use appropriate storage methods to prevent corrosion or damage before installation.

10. Expert Advice: If you’re unsure about maintenance or replacement procedures, consult with the bearing manufacturer or a qualified technician for guidance and assistance.

By following these maintenance practices, you can extend the life of rod end bearings, reduce downtime, and ensure the reliable performance of the systems in which they are used.

Advantages of Rod End Bearings

Rod end bearings offer several advantages compared to other bearing types, making them suitable for specific applications that require articulation, flexibility, and precise control. Here are some key advantages of rod end bearings:

- Articulation: Rod end bearings are designed to provide articulation, enabling movement in multiple directions. They allow for angular misalignment, making them ideal for applications that require flexible connections and motion control.

- Angular Misalignment: They can accommodate both static and dynamic angular misalignment. This ability to handle misalignment is a significant advantage in applications where components may not align perfectly.

- High Load Capacity: Rod end bearings are capable of handling both static and dynamic loads. They are used in applications where significant forces or loads need to be transmitted, such as in heavy machinery and construction equipment.

- Precision: These bearings provide precise control and movement. They are often used in applications where accurate positioning and control of mechanical components are essential, such as in aerospace and robotics.

- Corrosion Resistance: Many rod end bearings are available with corrosion-resistant coatings or materials, making them suitable for use in challenging environments, including marine and industrial settings.

- Durability: Rod end bearings are built to withstand harsh conditions, making them durable and long-lasting. They can handle the rigors of heavy-duty applications, ensuring reliability and performance over time.

- Versatility: These bearings find applications in a wide range of industries, from automotive and aerospace to industrial machinery and marine. Their versatility is a significant advantage for engineers and designers.

Overall, rod end bearings excel in applications that require a combination of articulation, load-bearing capacity, and precision. Their ability to handle misalignment and provide reliable performance in demanding environments makes them a preferred choice in various industries.

editor by CX 2024-04-16