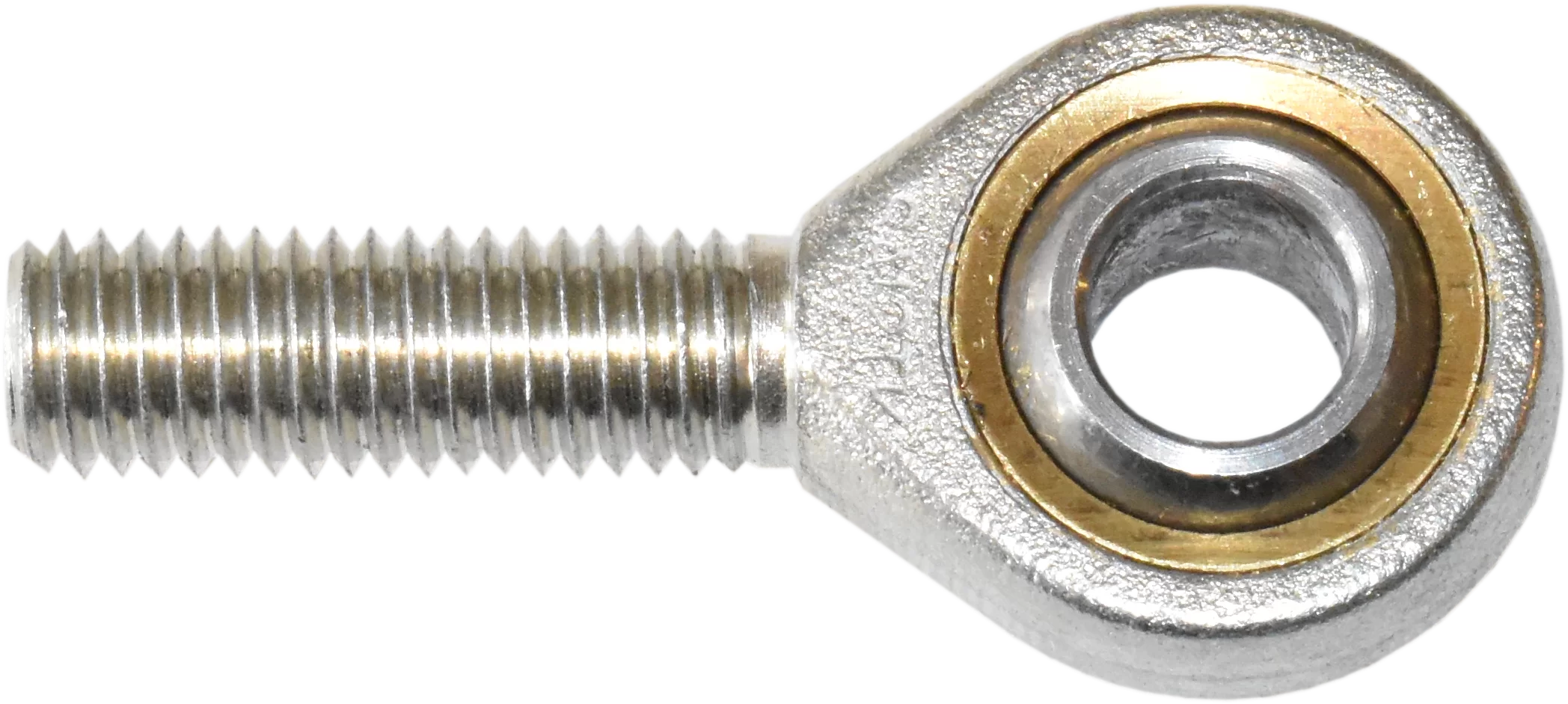

Product Description

Impact of Temperature Variations and Environmental Conditions on Rod End Bearing Performance

Rod end bearings can be affected by temperature variations and environmental conditions, which may impact their performance. Here’s how these factors come into play:

1. Temperature Variations:

Temperature changes can influence the lubrication and material properties of rod end bearings. Extreme cold can cause lubricants to thicken, potentially leading to increased friction and reduced efficiency. On the other hand, high temperatures can cause lubricants to thin, which may result in inadequate lubrication and accelerated wear. Proper lubrication and material selection are crucial to ensure that rod end bearings operate optimally across a range of temperatures.

2. Contaminants and Moisture:

Industrial environments often expose rod end bearings to contaminants such as dust, dirt, and chemicals. Additionally, moisture and humidity can lead to corrosion and reduced bearing lifespan. Seals and boots can help protect rod end bearings from these elements, maintaining their performance and preventing premature failure. Regular maintenance, including cleaning and re-lubrication, is essential to counteract the effects of contaminants and moisture.

3. Corrosion Resistance:

Rod end bearings are available in various materials, including stainless steel, which offers excellent corrosion resistance. This is especially important in environments where exposure to moisture or chemical agents is common. Choosing the right material for the specific environmental conditions is crucial to prevent corrosion-related issues and ensure the long-term functionality of the bearings.

4. Material Expansion and Contraction:

Temperature variations can lead to the expansion and contraction of materials. This can affect the clearances within the bearing, potentially causing issues such as increased play or reduced load-carrying capacity. Proper bearing design and material selection, as well as regular inspections, can mitigate these effects.

5. Lubrication Intervals:

In extreme temperature or environmental conditions, more frequent lubrication may be necessary to maintain optimal performance and protect rod end bearings from premature wear. Lubricants should be chosen based on their suitability for the given operating conditions.

Overall, temperature variations and environmental conditions can impact rod end bearing performance. Proper maintenance, material selection, and environmental safeguards, such as seals and boots, are essential to ensure that rod end bearings continue to function reliably in diverse operating environments.

Challenges and Solutions in Managing Load and Misalignment in Rod End Bearings

Rod end bearings often face challenges related to load capacity and misalignment in various applications. Here are the common challenges and solutions:

1. Radial and Axial Loads:

Challenge: Rod end bearings need to handle both radial and axial loads simultaneously in many applications.

Solution: Select rod end bearings with appropriate load ratings and materials to ensure they can withstand the expected loads. Also, proper maintenance and lubrication are essential for maximizing load-carrying capacity.

2. Misalignment:

Challenge: Misalignment can cause premature wear and reduced bearing lifespan.

Solution: Use self-aligning rod end bearings or incorporate spherical plain bearings to compensate for misalignment. Regular inspection and maintenance to correct any alignment issues are crucial.

3. Corrosion and Contaminants:

Challenge: Exposure to moisture, chemicals, and contaminants can lead to corrosion and damage.

Solution: Choose rod end bearings with suitable protective coatings or seals, such as PTFE liners or rubber boots, to prevent contaminants from entering. Stainless steel bearings offer enhanced corrosion resistance.

4. Lubrication:

Challenge: Inadequate lubrication can result in increased friction, overheating, and premature failure.

Solution: Follow the manufacturer’s lubrication recommendations and maintenance schedules. Proper lubrication ensures smooth operation and extends bearing life.

5. Shock and Impact Loads:

Challenge: Applications with frequent shock and impact loads can subject rod end bearings to excessive stress.

Solution: Choose rod end bearings with robust construction and materials to withstand shock loads. Regular inspections are necessary to detect early signs of damage.

By addressing these challenges with appropriate solutions, rod end bearings can perform optimally and provide long-lasting service in a wide range of applications.

Scenarios Requiring Articulation and Pivoting with Rod End Bearings

Rod end bearings are essential components in scenarios where articulation and pivoting are crucial. Here are some examples:

- Vehicle Suspension: Rod end bearings in a vehicle’s suspension system allow articulation of the wheels, ensuring a smooth and controlled ride, especially on uneven terrain.

- Aircraft Control Surfaces: In aviation, rod end bearings enable the pivoting of control surfaces like ailerons, elevators, and rudders, providing precise control over an aircraft’s movements.

- Robotic Arms: Rod end bearings facilitate the articulation and pivoting of robotic arms in manufacturing, assembly, and medical robotics, allowing for precise and flexible movement.

- Construction Equipment: Heavy machinery such as excavators and cranes rely on rod end bearings for articulation in booms, buckets, and other moving parts for effective operation.

- Marine Steering Systems: Rod end bearings play a vital role in boat steering systems, allowing articulation of the outboard motor or inboard-outboard drive unit.

- Agricultural Machinery: Tractors and combines use rod end bearings to articulate and pivot components in the steering and hydraulic systems for farming operations.

- Rail and Transportation: In rail systems, rod end bearings help with the articulation of train doors, ensuring safe and efficient passenger entry and exit.

- Conveyor Systems: In material handling, rod end bearings assist in the pivoting and articulation of conveyor belt rollers and other components for the smooth movement of goods.

- Sports Equipment: Fitness machines like elliptical trainers use rod end bearings to facilitate articulation in pedal arms, allowing users to exercise effectively.

These examples demonstrate the versatility and importance of rod end bearings in various industries where articulation and pivoting are essential for optimal performance and control.

editor by CX 2024-04-08